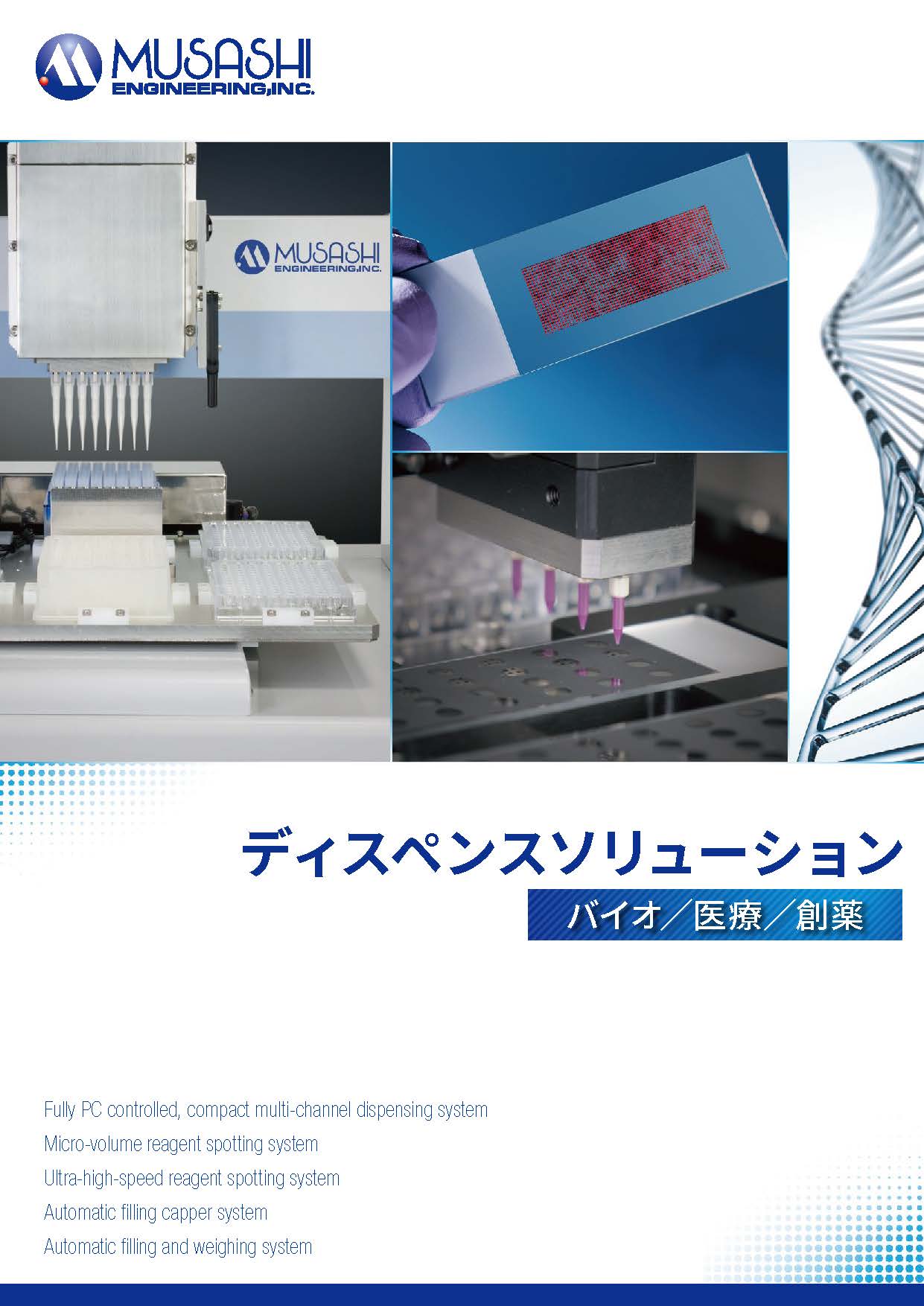

Bio, Medical and Drug Discovery

Dispense solution

High-precision dispensing technology is utilized in all fields of liquids such as pharmaceuticals and cosmetics, bio and analysis Industry. MUSASHI is responsible for the production of automatic Dispensing equipment required in various manufacturing and research fields. By automating work performed manually, it helps to reduce costs and hassle, prevent errors, and improve work accuracy.

Analysis preprocessing

Analytical preprocessing is a series of operations to prepare and prepare in an appropriate state before analyzing the sample. In this process, it is very important to ensure the accuracy and repeatability of measurements, and to optimize the samples according to the characteristics of the equipment and methods. It supports protocols in small areas (μL to mL) while suppressing the det volume.

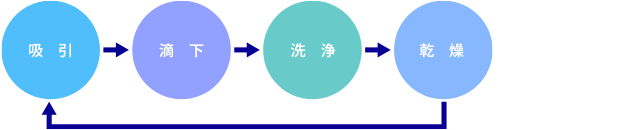

Main process of analysis preprocessing

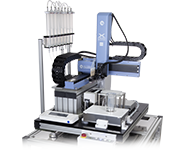

Divide the sample in an appropriate manner and save the desired analysis target. Semi-automates the sampling process for separating synthetics from organic synthesis equipment. The compact and simple design makes it possible to incorporate into various devices.

The work of dividing the sample by a certain amount. The highly accurate Dispensing determines the reproducibility of analysis results.

Our products are compatible with liquid and powder samples, fully automated from chip mounting to Dispensing. You can set the Dispensing amount separately for each pipette. It is compatible with various containers such as microtubes, plates, and vial bottles.

System example

Adjust multiple types of samples to the appropriate concentration.

Dilution amount and dilution ratio can be easily set. Mixing operation is possible by mixing function. Since the rack of the analyzer can be mounted as it is, the flow to analysis is smooth.

System example

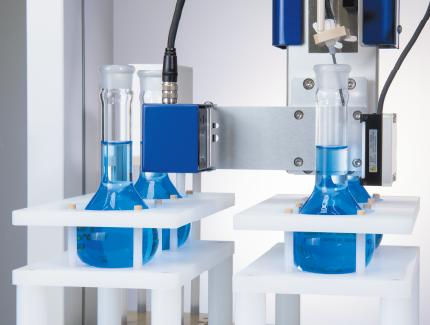

The camera recognizes the mark of Mesflasco with the camera, automatically adjusts the position of Meniscus against the mark, and reduces the variation in position by the worker.

System example

Analysis Pretreated Products Quick Reference Table

| Products | Organic Synthetic Extraction System |

Pitch variable 4 series Pipet Master |

Dispensing Dilution System |

Preparation system |

Filling up system for volumetric flask |

|---|---|---|---|---|---|

| Dispensing / Filling Amount |

〜50mL | 0.5μL〜1mL | Sample: 〜10mL Dilution: 〜50mL |

Pipette head: 0.5〜20mL Syringe pump: 〜50mL |

10mL to 250mL |

| Dispensing / Filling method |

Volume weighing type | Volume measurement | Volume measurement | Volume measurement | Pump type |

| Contami Avoidance mechanism |

― |

Pipette chip |

Pipette head: Automatic loading and unloading of chips |

Pipette head: Automatic loading and unloading of chips |

― |

| Sample Collection |

|

|

|||

| Dispensing |

|

|

|

||

| Dilution |

|

|

|

||

| Multiple specifications |

|

|

|

Reagent spotting

This is a process in which specific reagents are applied to the surface of materials and devices used for inspection and experimentation. Dispenser is an indispensable technology in the modern biotechnology field that requires micro-quantification and reproducibility of samples.

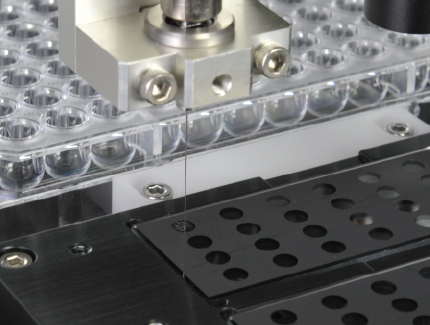

This is the process of applying a small amount of liquid samples accurately to a specific substrate (such as a slide glass or a microplate). It is used in various scenes such as pharmacological screening, antibody testing, and DNA microarrays.

In our company, ultra-fine (nL) spotting of multiple reagents is possible. Prevents contamination and realizes high-precision and high-speed application. It is highly reproducible and spots the specimen at a uniformly accurate position.

System example

Reagent Spotting Product Quick Reference Table

Reagent Filling

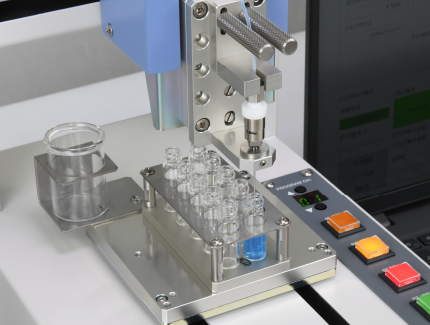

Filling refers to the process in which liquid and powdered reagents are dispensed and sealed in an appropriate container. It is frequently used in the manufacture of diagnostics, medical reagents, research reagents, or bioproducts. Reagent Filling requires strict management to stabilize product quality and enable accurate use.

Filling and capping are a continuous process of encapsulating chemicals into containers and protecting them from external environments.

One robot consolidates a series of operations from “cap opening → chemical solution Filling → cap closing”. Efficient production and product uniformity are maintained.

Fill the powdered material in the appropriate container to measure the exact amount. It is possible to monitor weight in real time, to determine OK/NG due to excess or deficiency of weight, and to manage the log of scale value.

Reagent Filling Product Quick Reference Table

| Products | Chemical solution Filling & Capping System (pipet type) |

POWDER SHOT & weighing system |

|---|---|---|

| Output amount | 0.5μL〜20mL | Several μL to 5000 μL |

| Discharge method | Volume weighing type | ー |

| Contami Avoidance mechanism |

Pipette chip Automatic attachment and removal |

Automatic loading and unloading of chips |

| Capping |

|

|

| Scale weight |

|

|

Support for mass production

High-throughput screening (HTS) and large-scale experiments require fast dispensing of large amounts of reagents and samples. Fully automatic dispensing machine allows you to work efficiently. It is possible to reduce costs by working with the minimum required amount. It also prevents re-starting the test due to Dispensing error.

FAD2500SD

| Output amount | 0.5μL~ |

| Discharge method | ※ |

| Contami Avoidance mechanism |

※ |

| Scale weight |

|

| Log management |

|

※It depends on the mounting head.

Recommended catalog

Dispense Solutions <Bio/Medical/Drugment>