Examples of introduction

Dispenser (dispense system) is used in the manufacturing process of many products around us.

Here are some examples of applications that have been attracting attention recently, as well as examples of solving problems in production sites by introducing Dispenser of Musashi Engineering.

Examples of introduction

Improve grease application in Dispenser!

We will introduce solutions that solve problems related to grease application, such as variations in the amount of application, application in difficult-to-access areas, and wide-ranging applications.

Examples of introduction

Manual dispense

System

Improve manual application process in Dispenser, Musashi.

Realize the ease of use, versatility, and low cost required for manual Dispenser. It is easy for anyone to use with simple operation, and has versatility for various applications. In addition, it can be introduced at low cost, and it can be easily improved operational efficiency.

Examples of introduction

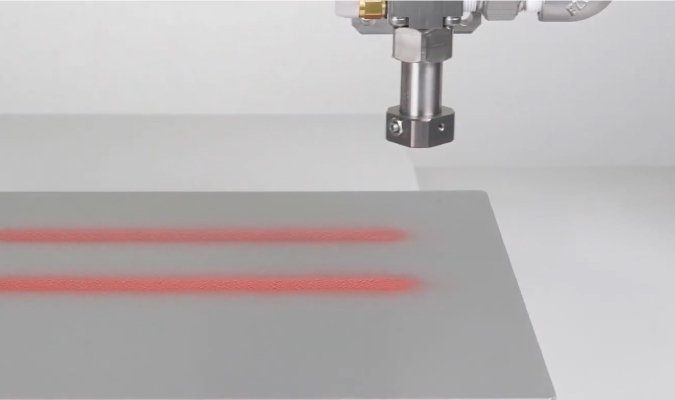

3 reductions with maskingless thin film spray application!

Introducing the benefits of precise spray application, including examples of adoption in the automotive industry. Improve productivity by maskingless spray application.

Examples of introduction

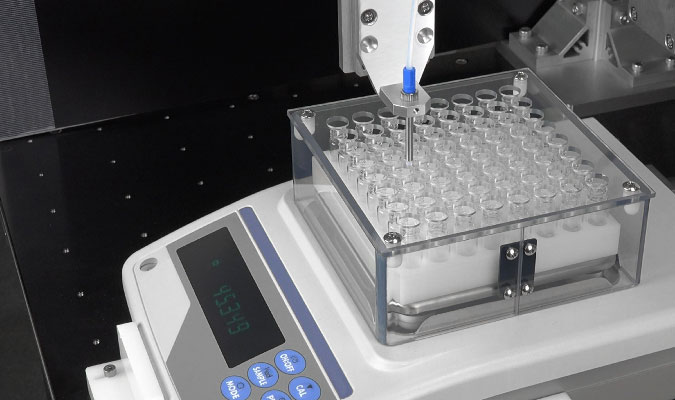

Automatic Weighing System

Automatic recording of weighing results in analysis eliminates errors in input of results associated with manual input.

In addition, it improves the credibility of the data. When traceability management is questioned, it is possible to automatically collect and manage data management.

Examples of introduction

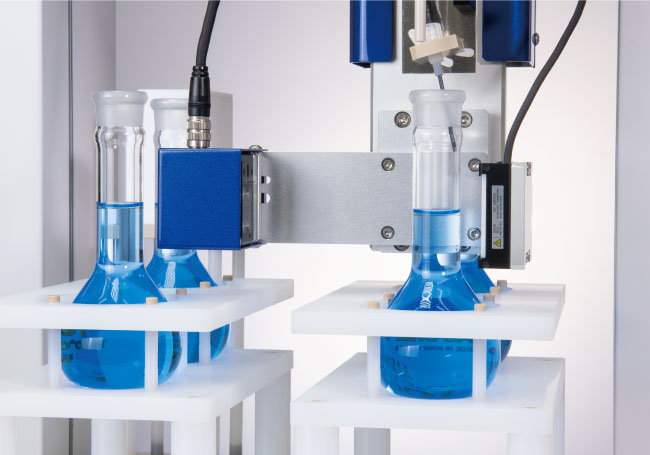

Filling up system for volumetric flask

Many of the analytical specimens are filled with mesflasco. At that time, many round trips are filled with pipettes, which puts a burden on your hands.

In addition, the Filling up to the line can fluctuate depending on the worker's skills.

With the automation of the equipment, it is possible to achieve stable female-up by high-volume Filling and mark automatic stop function.

Examples of introduction

Analytical preprocessing automation system

Various component analysis is conducted as part of the material quality assurance.

When setting specimens in the laboratory equipment, various dilutions and additives must be mixed with the specimen to make them suitable for analysis. However, the Dispensing work is mostly human. In particular, when the output result of the ppm order is required, the result will fluctuate depending on the sample production skill of the worker.

Examples of introduction

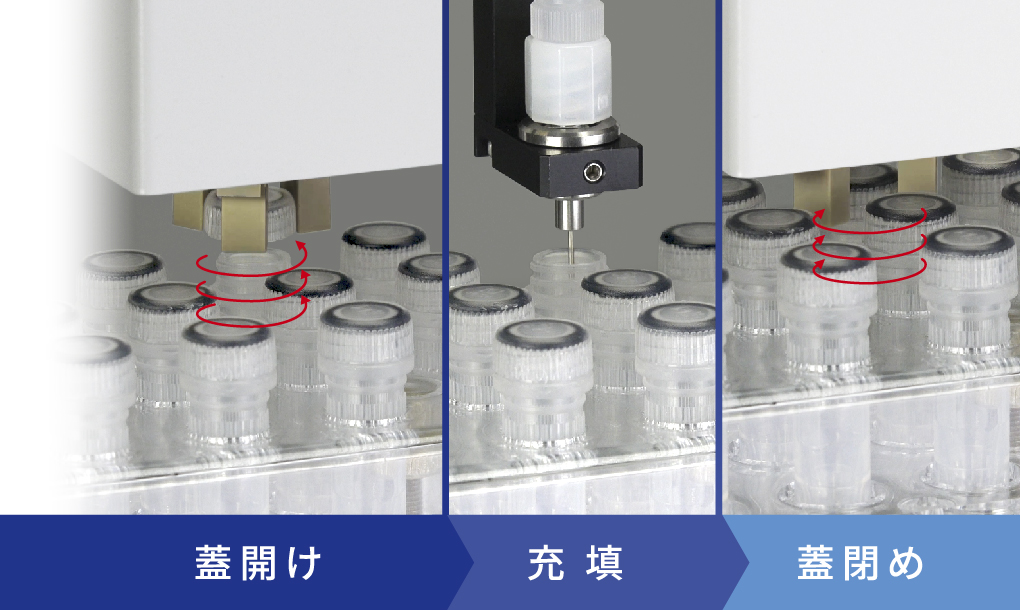

Chemical solution Filling & Capping System

Filling chemical solution for screw cap tubes, conical tubes and vial bottles, and semi-automated cap opening and closing operations.

One Desktop robot achieves opening and closing of the chemical solution Filling and cap.

Examples of introduction

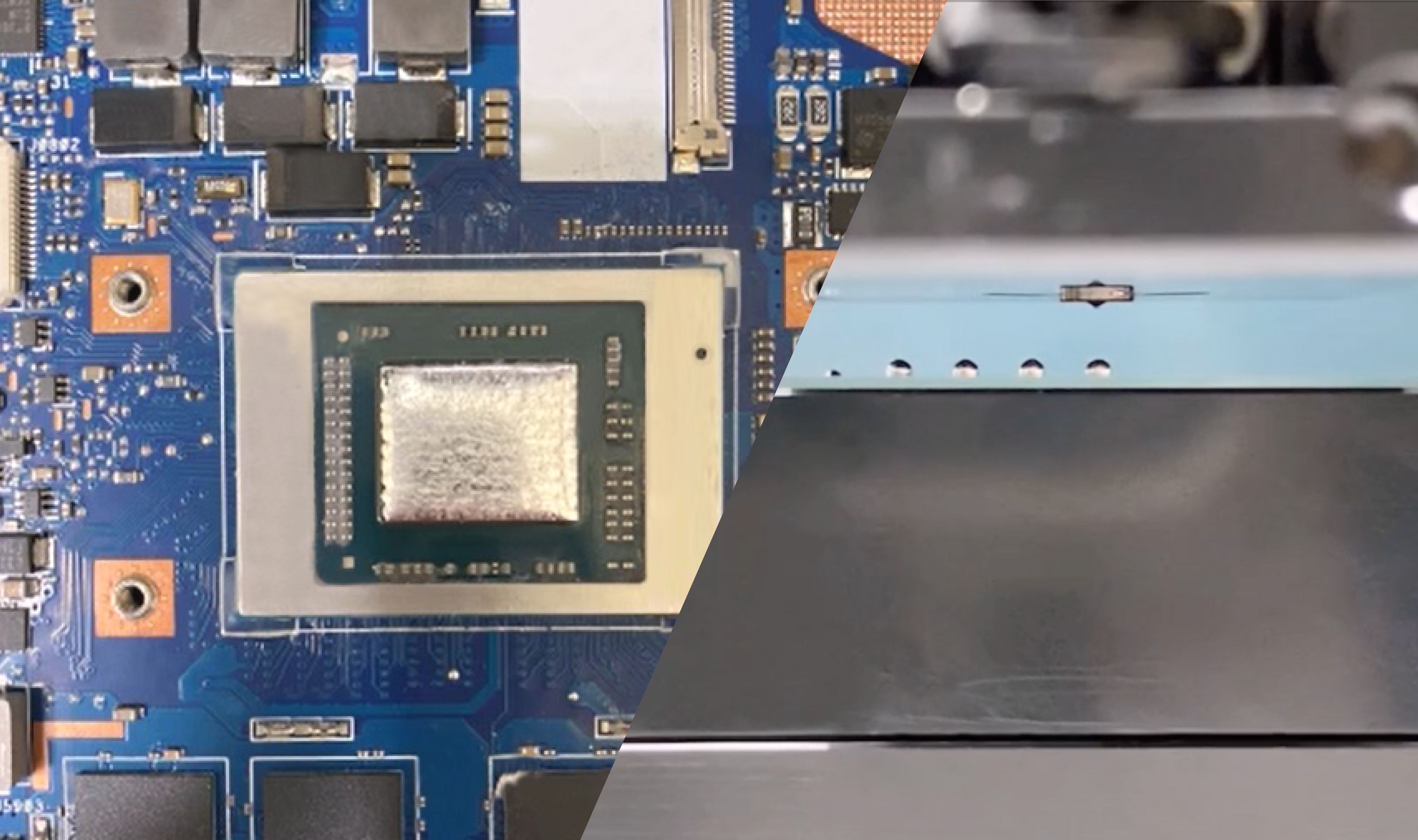

Jetting of liquid metal

The adoption of liquid metals is progressing in CPU Heat dissipation, a high-performance gaming PC.

High-speed and stable application with contactless Jet dispense.

Examples of introduction

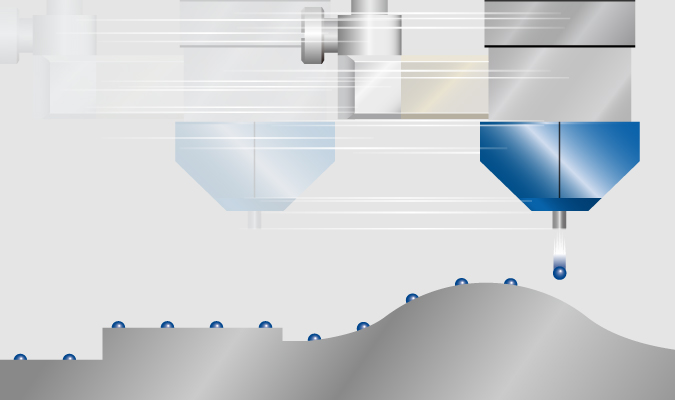

Dispensing of One/Two-part Thermal management materials

A thermal management solution that supports new technologies such as next-generation power semiconductors, 5G, and IoT.

High-precision application of Heat dissipation materials with an increasingly high thermal conductivity is required.

Examples of introduction

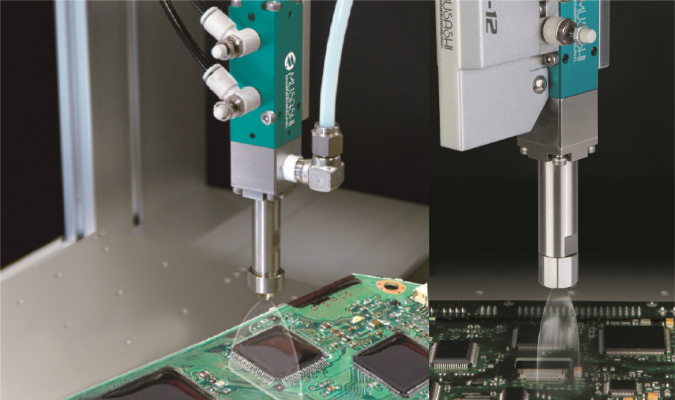

Contactless Jet dispense

Fast speed, no contact accident with workpieces, can be applied from lower, horizontal, and diagonally.

There are many advantages that are difficult for contact types, and the number of cases of introduction is increasing.

Examples of introduction

Maskless coating

A conformal coating to protect mounting substrates (PCBs).

We have improved quality, improved productivity, and improved environment by changing from manual brush coating to semi-automatic and fully automatic coating equipment.

Examples of introduction

3D Alignment and following Dispensing

There is no problem even if the workpiece has different distortions or warpages, or if the workpiece is misplaced in the palette.

The dispense machine automatically senses and performs optimal application.

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact