Ultraprecision, ultramicro fluid control technology

Fluid control technology indispensable to the production of familiar products

Musashi Engineering continues to lead Japan and the world in "dispense technology" that controls liquid materials quantitatively and precisely.

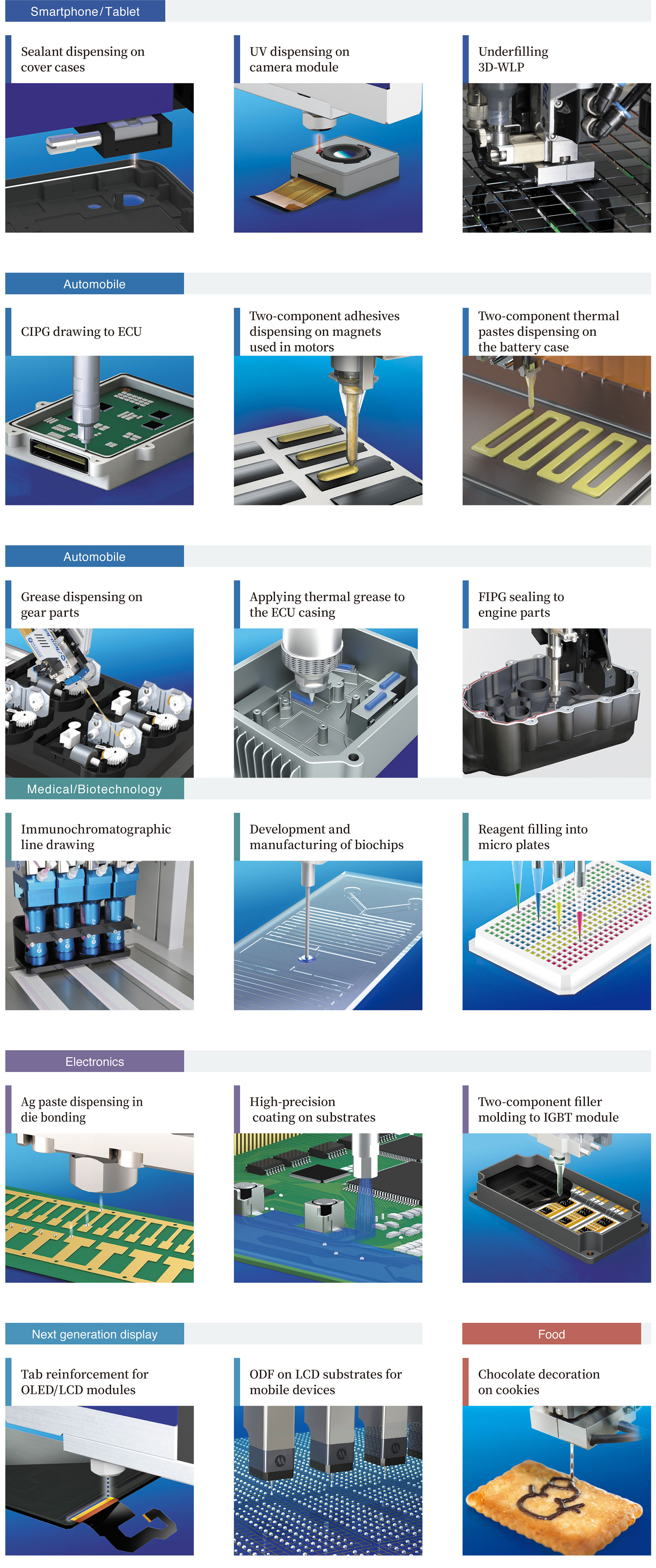

Dispenser (Dispense System), which embodies the dispense technology, is used in the manufacturing process of many products around us, from mobile devices such as smartphones, VR and AR goggles, smartwatches, digital devices such as personal computers, tablets and game consoles, home appliances such as TVs, air conditioners and refrigerators, as well as automobiles with remarkable technological innovations such as autonomous driving and EVs, to living equipment such as kitchens and bathrooms. In recent years the application of dispensing systems have been expanded to medical care, medicine, biotechnology, food, and other areas as well.

Dispensers are used here.

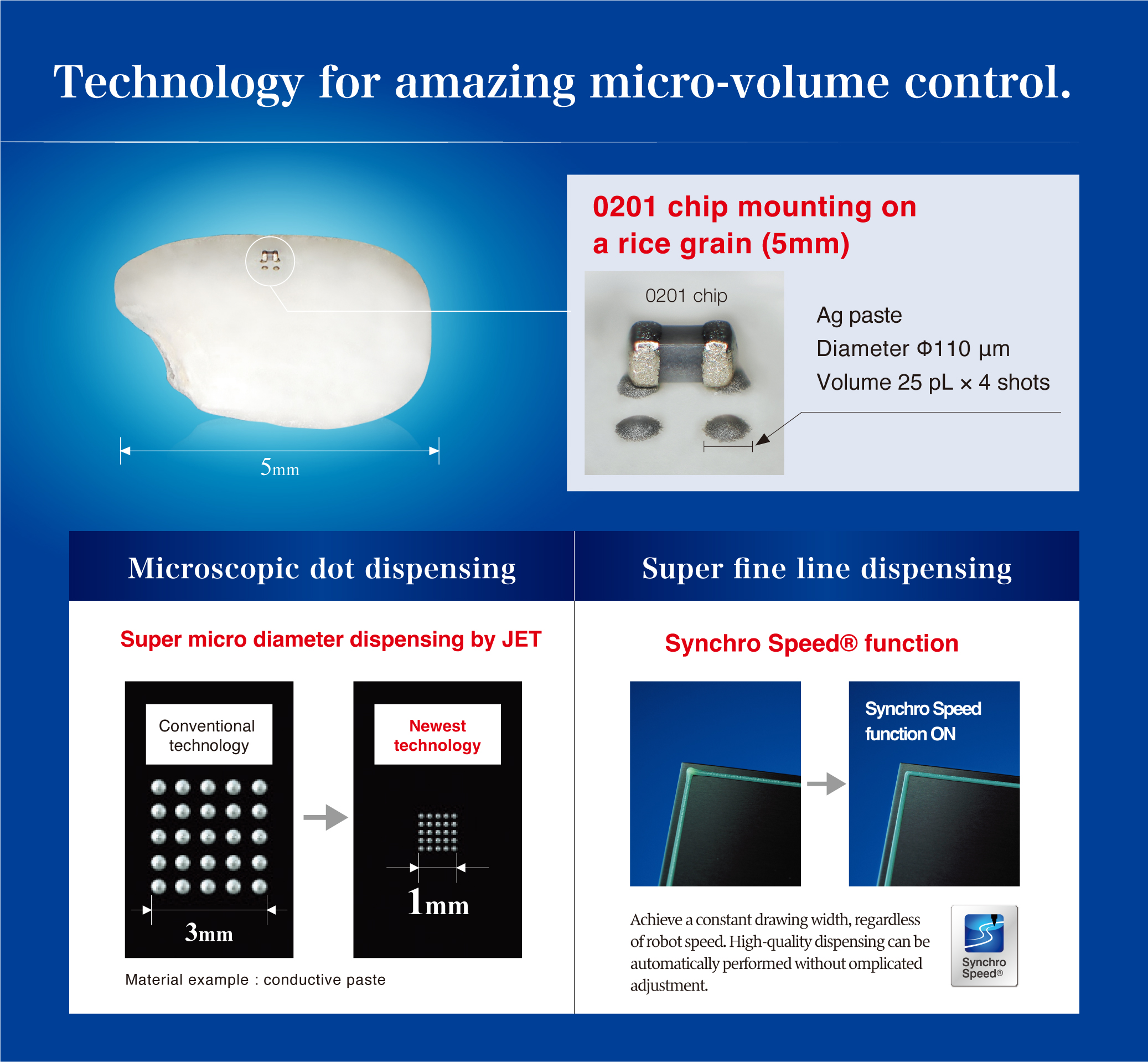

Control of fluids at the pico and nano levels

One of the advantages of Musashi Engineering is its technology to control fluids in microscopic region. The technology is a world that precisely controls a small amount of liquids at the pico-liter (pL: 1 trillion liter) and nano-liter (nL: 1 billion liter) levels. With the miniaturization and enhancement of electronic equipment, semiconductors and electronic components incorporated in these products are required to be more miniaturized, and our unique technology to control ultra-fine liquids is utilized.

In addition, the technology to control ultramicro fluids has been applied to the fields of medical care, medicine and biotechnology attracting attention in recent years. For example, in the process to develop new medicines, testing is repeated by combining compounds in thousands of ways. Our dispensing system has been deployed to perform these screening processes more accurately and more efficiently.

1pL (pico liter) = 0.000 000 000 001L (one trillionth of a liter)

1nL (nano liter) = 0.000 000 001L (one billionth of a liter)

Precision control technology to give shape to fluids

We support the world’s "Monozukuri” (manufacturing).

Musashi Engineering's Dispenser (dispense system) is used in many manufacturing processes at production plants around the world. Its application applications are diverse and boast a high global share in many processes. For example, the global share of the die bonding process of semiconductors and the ODF process of LCD panels for mobile applications is more than 80% (*).

We also have a high market share in Underfill for 3D-WLP, UV curable resin application for camera modules, and grease application for automotive parts.

This high share is achieved by Precision control technology to give shape to fluids, our dispensing technology that quantitatively and precisely controls a wide variety of liquid materials.

※Our estimate. It varies depending on the market and application.

We support "Monozukuri” (Manufacturing) in a variety of industries worldwide responding to various fluid materials and dispensing shapes.

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact