Conformal coating to protect mounting substrates (PCBs)

Case study maskless coating

Challenges

- The quality of the product depends on the skill of the worker due to manual brushing.

- Certain varieties with high difficulty can only be handled by specific skilled workers.

- Therefore, if the worker suddenly rests due to COVID-19 infection, the production volume will be limited.

- For varieties with an area where no application is prohibited, masking materials are pasted before brushing them, and it takes time.

- We are concerned about occupational health problems due to volatile compounds (VOCs) contained in liquids.

Measures

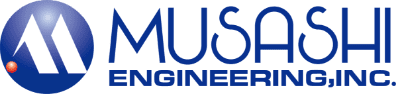

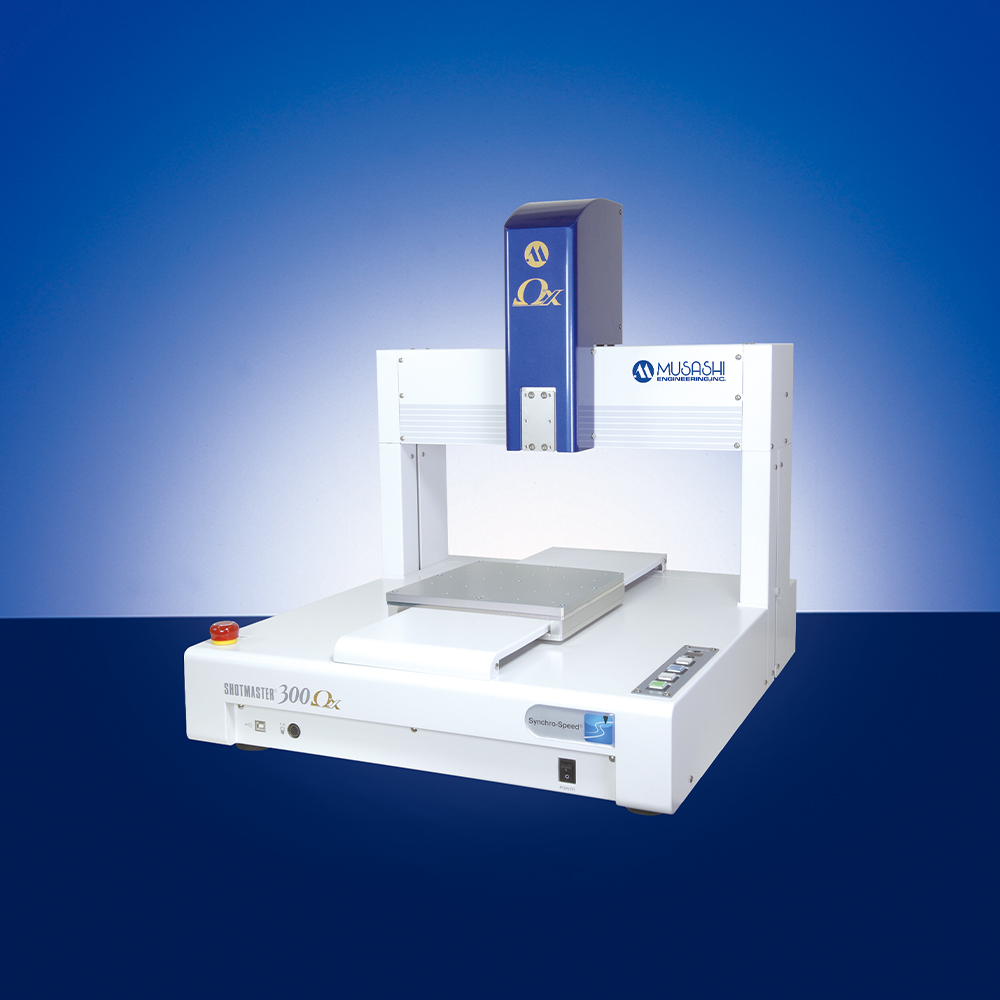

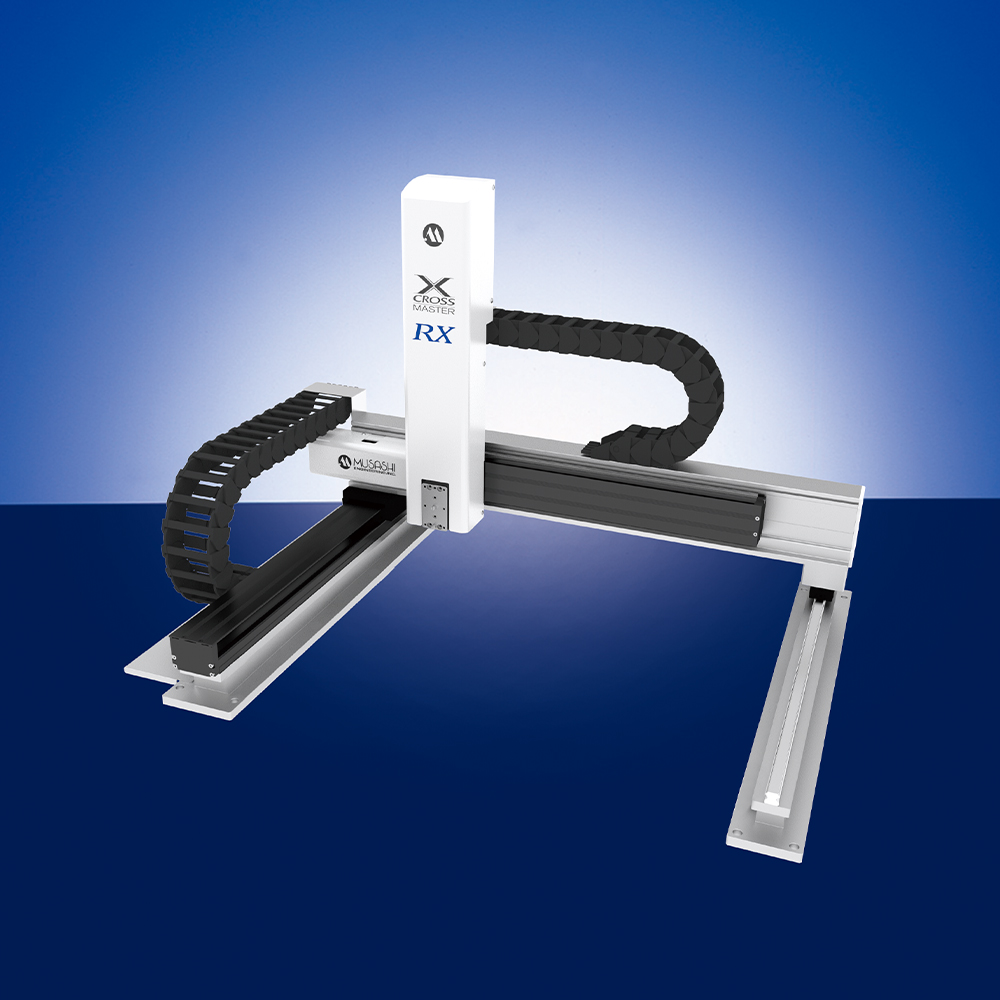

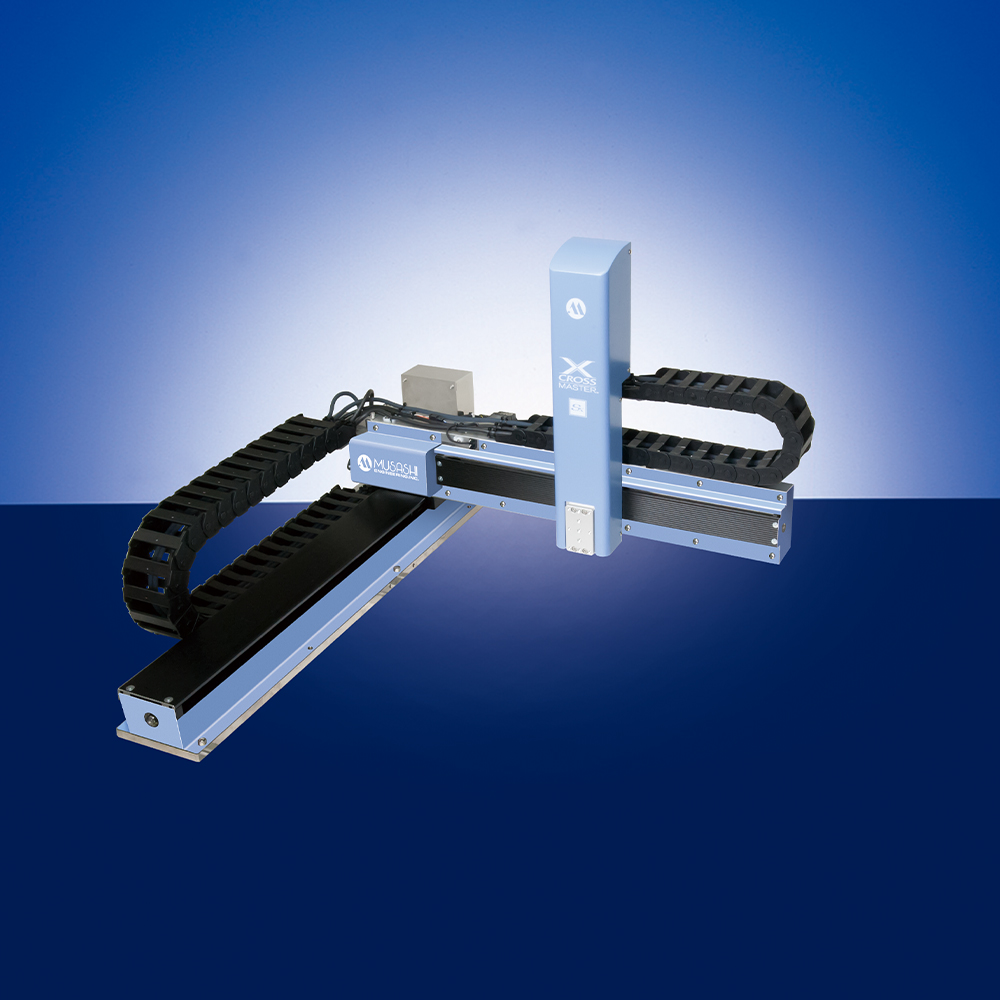

- Introduced semi-automatic application system utilizing Desktop robot and Fully automatic dispensing machine.

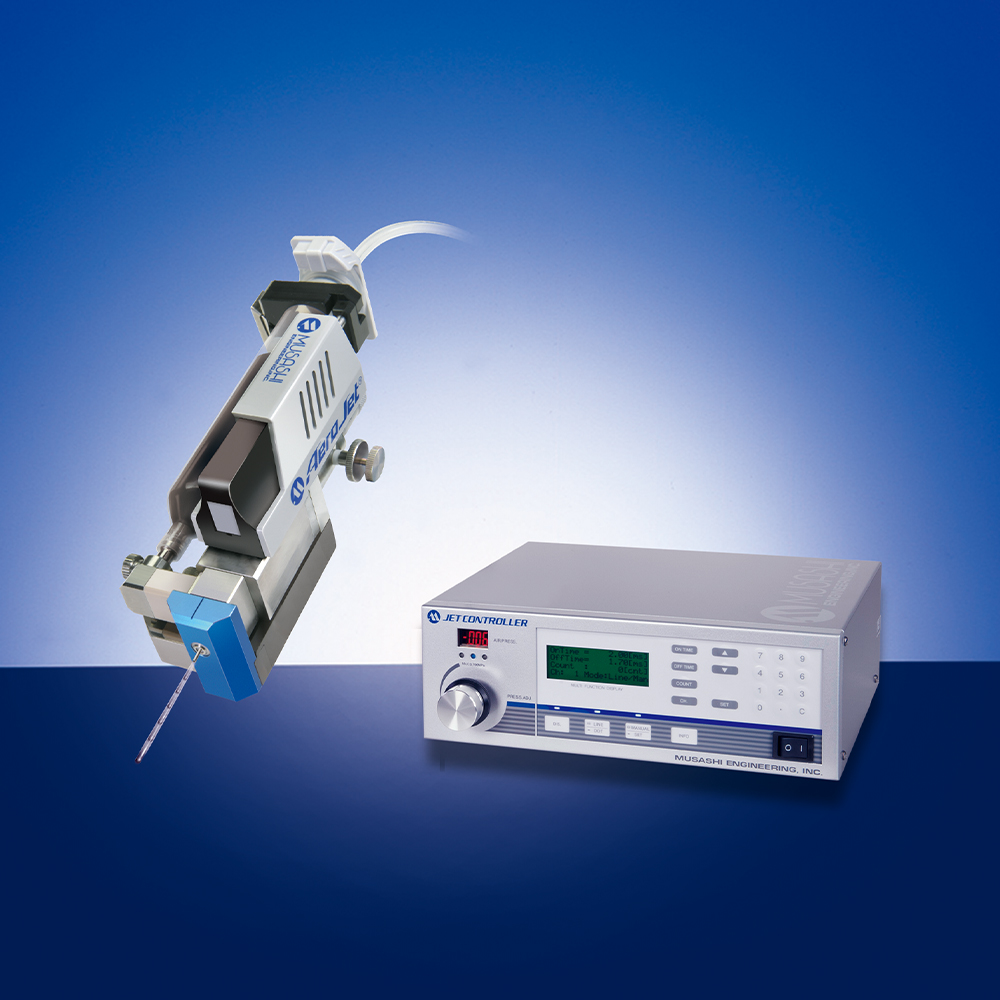

- Double use of JET Dispenser and coating valve for dispense head.

- In order to improve the environment, we introduced a safety cover with an intake and exhaust system.

Effect

- Regardless of the skill of the worker, no matter who is in charge, high-quality finish was achieved, and good quality was increased.

- With JET dispensing, "maskless coating" can be made, reducing the masking process. Productivity has improved.

- Curtain application with coating valves is carried out in areas with wide application areas. I tried to shorten the tact.

- The worker was isolated from the volatile of the liquid agent, eliminating the concern of health problems.

PROPOSED PRODUCTS

Proposed Products

OTHER CASES

Other Case Study

Filling chemical solution for screw cap tubes, conical tubes and vial bottles, and semi-automated cap opening and closing operations.

The adoption of liquid metals is progressing in CPU Heat dissipation, a high-performance gaming PC. High-speed and stable application with contactless Jet dispense.

A thermal management solution that supports new technologies such as next-generation power semiconductors, 5G, and IoT.

Fast speed, no contact accident with workpieces, can be applied from lower, horizontal, and diagonally.

There is no problem even if the workpiece has different distortions or warpages, or if the workpiece is misplaced in the palette.

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact