Improve grease application in Dispenser!

Case study Improved grease application in Dispenser!

Point of this case

(1) You can find common challenges when applying grease in Dispenser.(2) You can see the options of Dispenser according to your purpose.

(3) You can see specific examples of use and implementation.

Purpose of grease application

The grease is applied to smooth the sliding between parts. If the amount of grease is too large, it will take the time to wipe off the protruding parts, resulting in waste of materials and increased costs. Conversely, if the amount of grease is too small, the feeling of operation of the switch etc. may change or cause product defects. However, unlike adhesives, parts do not fix each other, so the importance of capital investment may be neglected.

| There is a lot of grease | Less grease |

|---|---|

| More work to wipe out protrusions increases | Impact on the feeling of operation of switches, etc. |

| Wasteful material costs | There is a noise of friction, etc. |

Case 1

Improve the amount of application of grease!

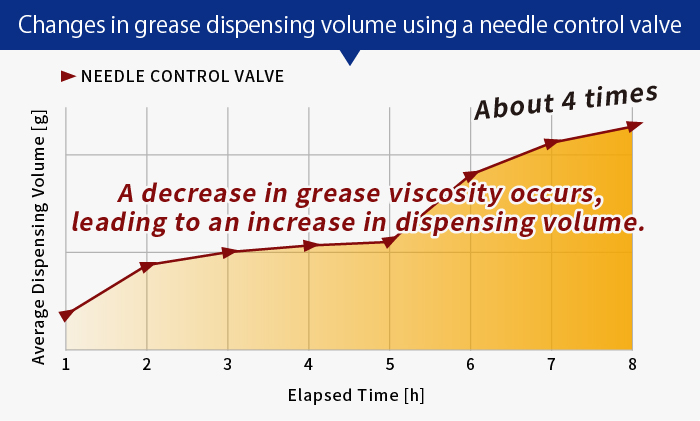

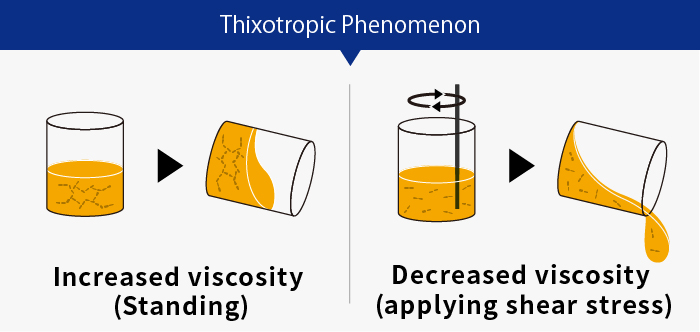

Factors of varying amount of grease application

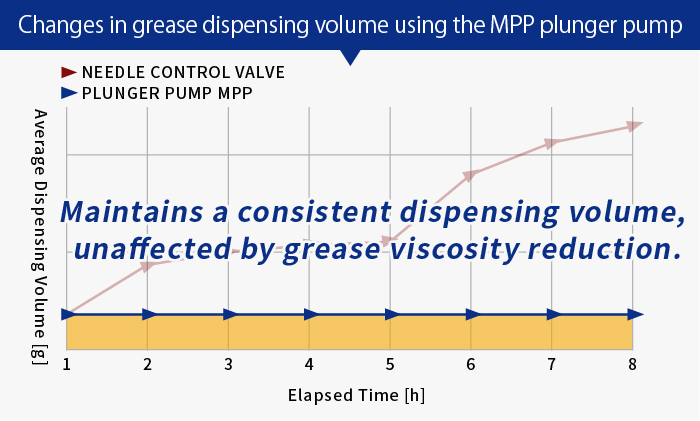

Unlike adhesives, grease does not harden, so it is easy to think that it is a liquid whose viscosity is difficult to change. However, many greases have the property of degrading viscosity when transitioning from a stationary state to a fluid state (thixotropy phenomenon). Even if the discharge condition is constant, the discharge amount may change due to this change in viscosity.

2 products suitable for quantitative application of grease

Dispenser, which can discharge a fixed volume from Dispenser, regardless of the viscosity of the material,

①Plunger pump type MPP 2 MOHNO Type MOHNOMASTER.

These Dispenser enables quantitative application of grease.

The differences in features are as follows.

| MPP | MOHNOMASTER | |

|---|---|---|

| Method | Plunger pump | Mono |

| Output accuracy | ★★★ | ★★☆ |

| Spill speed | ★★☆ | ★★★ |

| Running cost | ★★☆ | ★☆☆ |

Case 2

Realize grease application automation in difficult-to-paint position!

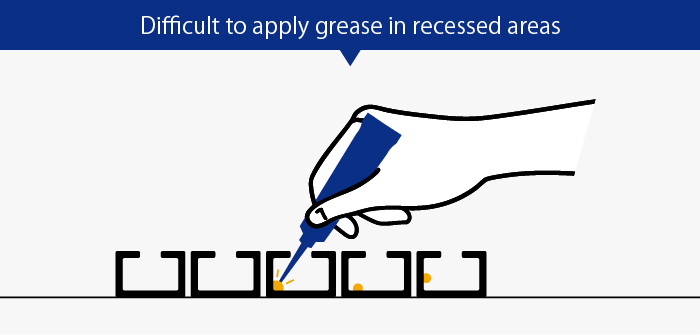

Challenges in automatic application of grease

In many cases, the part where the grease is applied is the part where the parts and parts fit together, and it is located in a place where it is difficult to access. Therefore, it is difficult for Dispenser needles and Nozzle to reach, which can be a barrier to automation of grease application.

Jet Dispenser with excellent application in narrow area

Jet Dispenser is able to apply grease from a distance without invading the Needle Nozzle into a narrow area. In addition, since the direction of application is not limited to just below, dispensing can be performed at applications where it is difficult to access.

Two points to improve the reliability of application

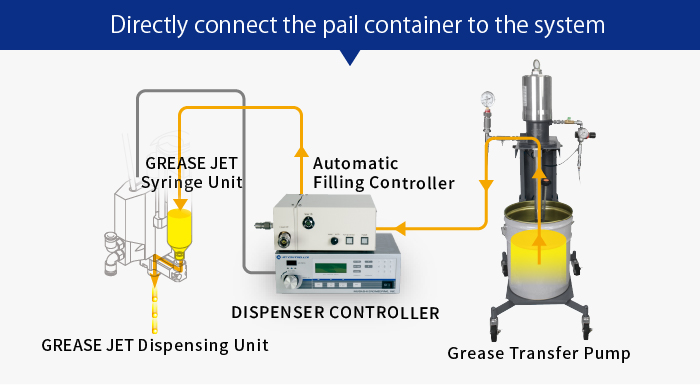

Refilling the grease is a time and effort, but at the same time, the liquid agent gets bubbles during the work, causing poor application. When using jet Dispenser, we propose a tank pressure transmission system and Peer can application system that can be set directly as a grease can.

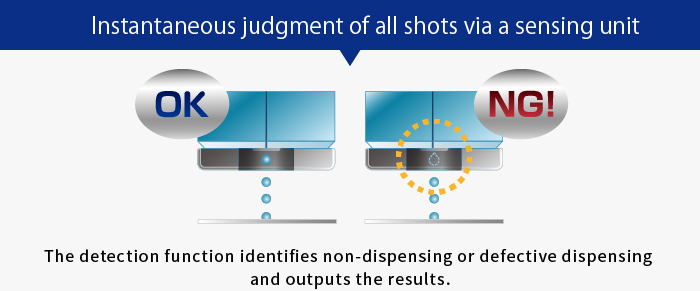

Even in the unlikely event that the liquid agent contains bubbles, it is possible to detect empty strikes by using a misshot detection unit.

Note: Support for AeroJet series only

Case 3

Reproduce the brushing of grease with spray technology!

Examples of automatic application of grease in Dispenser

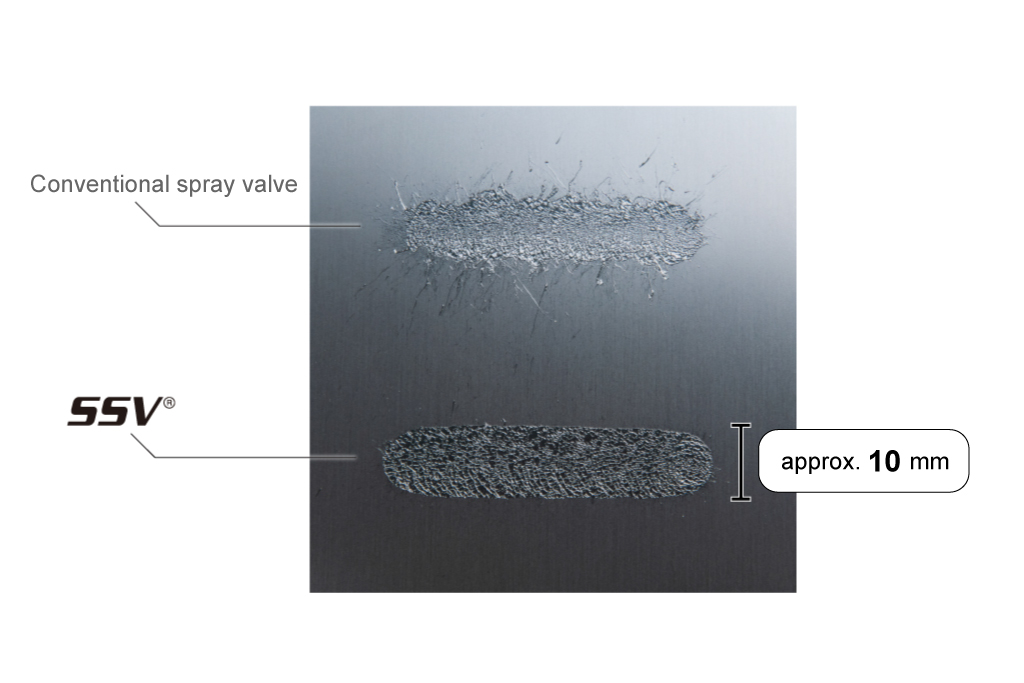

Dispenser applies grease in dots and lines. Therefore, it is not possible to apply grease in a short time to areas with a width of more than 10 mm, such as rail-shaped parts. Even if you try to apply the grease using a spray valve for the purpose of expanding the application shape, it is difficult to spray because of the high viscosity of the grease, and the grease splashes and does not get satisfactory quality.

Spray valves that enable wide-ranging and bulk application of grease

The SSV-1 spray valve developed by our company has made it possible to spray applications of high viscosity liquids by improving the air flow path for atomizing from conventional ones. As a result, even if it is a wide range of grease applications, it can be realized in a short time, and the thickness and quantity of grease can be controlled stably.

Comparison of grease application samples

Summary

| Examples | 1 | 2 | 3 |

|---|---|---|---|

| Challenges | Variability in the amount of application | Nozzle Access | Wide-ranging batch application |

| Solution | Quantitative discharge Dispenser | Jet Dispenser | High Viscosity Spray Valve |

| Products |

We introduced three examples according to the challenges in grease application. Please feel free to contact us from the link below for testing and rental of demonstration machines.

PROPOSED PRODUCTS

Proposed Products

OTHER CASES

Other Case Study

The adoption of liquid metals is progressing in CPU Heat dissipation, a high-performance gaming PC. High-speed and stable application with contactless Jet dispense.

Fast speed, no contact accident with workpieces, can be applied from lower, horizontal, and diagonally.

A conformal coating to protect mounting substrates (PCBs).

There is no problem even if the workpiece has different distortions or warpages, or if the workpiece is misplaced in the palette.

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact