3 reductions with maskingless thin film spray application!

Case study Spray Valve reduces “time,” “cost,” and “hours”

Point of this case

- The advantages and disadvantages of spray valves that are often used in the automotive industry.

- You can see the benefits of using a precise spray valve.

- You can see specific examples of use.

Features and Challenges of Spray Valve

Features

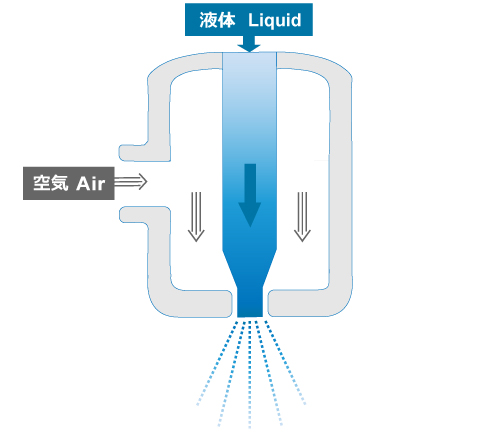

- A spray valve is a product that emits liquid in a mist form by simultaneously emitting air from outside the liquid outlet.

- Since thin films can be made over a wide area in a short period of time, they are used for painting body and parts, as well as for adhesion/sticking of interior and exterior parts.

Challenges

- As it becomes finely mist-like, it scatters around the area or soars into the air, so it may take time for human work such as masking on areas that are not painted and cleaning the surrounding environment regularly as a countermeasure.

Advantages and demerits of spray valves

| Benefits | Demerit |

|---|---|

| Can be applied extensively in a short time | Masking is required for parts that you don't want to paint |

| Can be applied in thin film | Because it dances in the air, there is a lot of waste of liquids. |

PROPOSED PRODUCTS

Proposed Products

Fine Spray Valve FSV-1

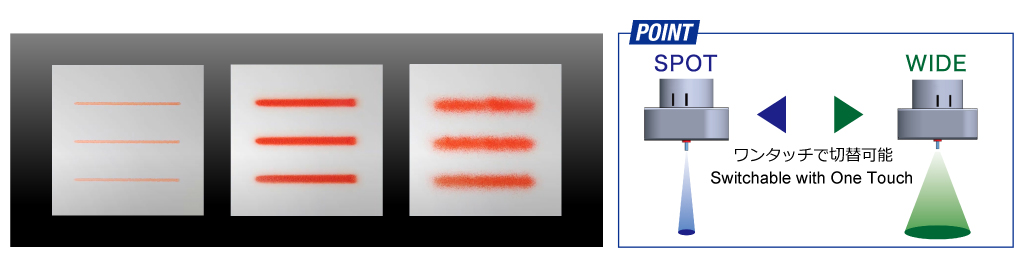

Our spray valve, FSV-1, has precision unique to Dispenser manufacturer, and by selecting 12 types of Nozzle and 2 types of application modes according to the required application shape and application range, it reduces scattering, realizes detailed application and maskingless spray application.

Various applications are possible in combination of Nozzle and application mode

FSV-1 contributes to three reductions through precise spray application

Reduce Masking masking work

Cut Costs Reduction of Material Costs

Minimize Cleaning Reduces cleaning time and number of times

Application examples in the automotive industry

- Apply primer to fix the exterior parts.

- Oil is applied to the cap parts of the tank.

- Apply grease to prevent friction of impane parts.

- Application of substrate coating agent to electrical substrate.

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact