What is Dispenser?

We have compiled answers to frequently asked questions. Please use it to solve basic information about Dispenser and questions about products and services.

For questions not listed below or more detailed inquiries, please feel free to contact us from this website.

What is Dispenser?

Definition of Dispenser

Dispenser is a tool for expelling liquids that can be found in various situations such as daily life and industrial sites.

In fact, it is often used in daily life, "Soap Dispenser" for shampoo and rinse, "Drink Dispenser" for pouring beverages installed in drinks bars such as family restaurants into glasses, and "Soft Ice Cream Maker" for home use are also friends of Dispenser.

Dispenser is a device that supplies a certain amount of liquids, pastes, etc., in various kinds. For example, we are active in various aspects of our daily life and industry, including cosmetics, Food, chemicals, pharmaceuticals, and industrial products.

Our Dispenser is classified as industrial Dispenser, and is developed and used to discharge liquid materials used in factories and other production sites "quantified" and "precision" and "apply" to the desired form.

The target liquid materials are diverse. For example, solder paste for electrical bonding parts, Heat dissipation material for releasing heat, Shading ink for blocking light, etc.

We have a lineup of various methods and types of Dispenser so that these liquid materials can be dispensed according to your various purposes, applications, environment and conditions.

Dispenser is active in various fields

The meaning and etymology of Dispenser

The word "Dispenser" comes from the English "dispenser". The word is derived from the Latin word "dispensare" and has the meaning of "sharing" and "distribution". The Latin word "dispensare" also consisted of "dis-" (dividing) and "pendere" (weighting) and originally referred to the act of dividing things evenly.

Dispenser, which we handle, means "liquid precision control device" in Japanese, refers to controllers and peripherals that supply liquids with high precision.

Roles and Functions of Dispenser

One of the main roles of Dispenser is to supply liquid materials accurately and uniformly. By using Dispenser, we can improve work efficiency and maintain product quality in many situations such as manufacturing and chemical experiments.

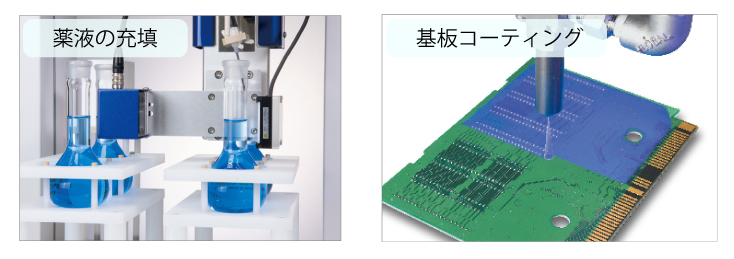

For example, in the pharmaceutical industry, Dispenser is used to accurately measure the amount of chemical solution and fill various containers such as small bottles. In cosmetic manufacturing, it is used to pack a uniform amount of cream into containers.

In other manufacturing industries such as the automotive industry, electrical and electronic industries, it is used to discharge liquids such as adhesives, lubricants, and Heat dissipation materials accurately and accurately at specified discharge volume. In addition to improving the quality of products, it plays a very important role in standardizing manufacturing processes and achieving mass production.

An example of a Dispenser application

Evolution through technological innovation

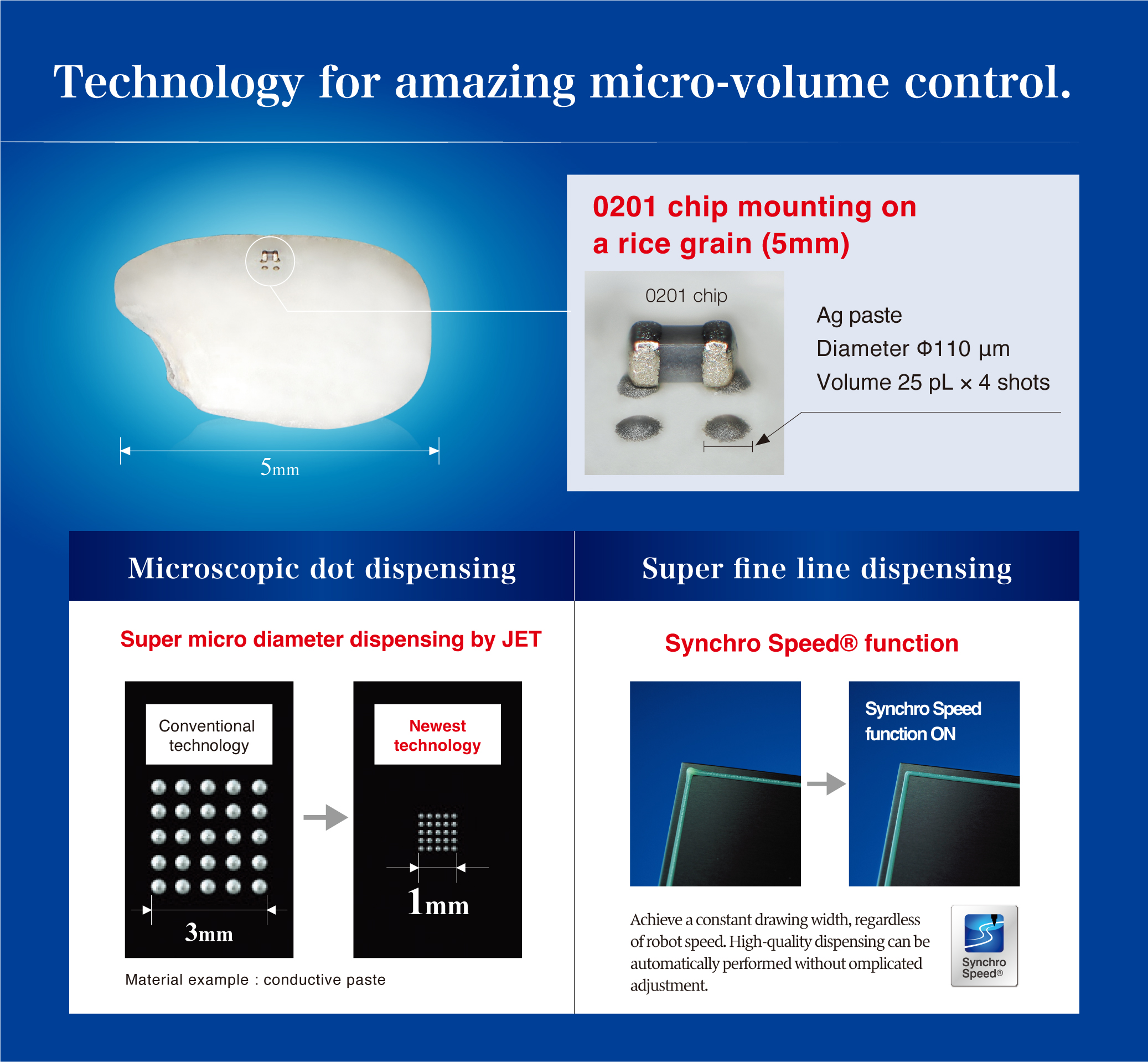

In Dispenser, various technologies such as the precision of application and the speed of application are greatly advanced. With the introduction of new technologies, more accurate and efficient Dispenser has been developed, and conventional manual automation has been further advanced. For example, in the production process of smartphones, it is necessary to perform extremely small applications with high accuracy, which are difficult to manual, with the miniaturization of products and improved performance.

Musashi Engineering is focusing on technology development to meet such demanding application requirements, and in the case of fine application, it has precise application technology that allows non-contact application of Ag paste with a diameter of 110 μm on rice grains (approximately 5 mm).

Cost reduction and consideration for the environment

Dispenser has the ability to control the amount of application according to the required amount, thus reducing waste of materials. In addition, accurate application improves the quality of the product and prevents the occurrence of defective products.

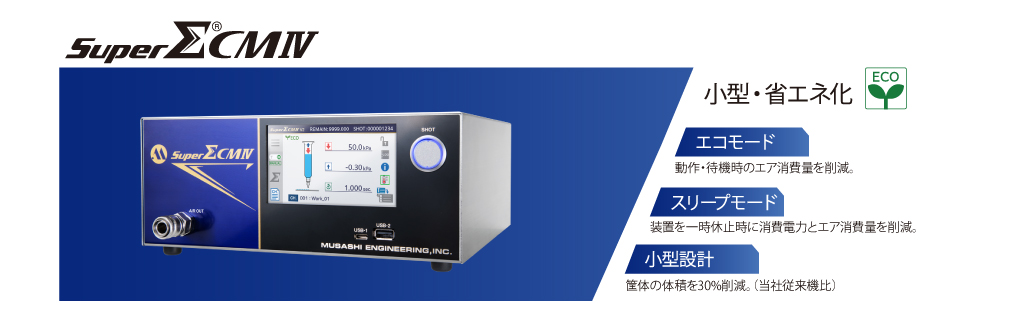

Consideration for the environment is also an important point. Using Dispenser reduces excessive use of materials, reduces waste, and saves resources and reduces environmental impact. In addition, the latest Dispenser can also reduce energy consumption in the entire manufacturing process by improving energy use efficiency in energy-saving modes. In addition, Dispenser, which can use environmentally friendly materials such as solvent-free coating materials, has also been developed to produce products while minimizing adverse effects on the environment.

Dispenser of Musashi Engineering

Musashi Engineering handles various types of industrial Dispenser, such as air pulse, jet and volume weighing. If you would like to know more about the type of Dispenser, please check the link below.

>Q&A: What kinds of Dispenser are there?

Other recommended links

>[Q&A] Can Dispenser be mounted on robots?

> Strengths of Musashi Engineering

>[Product List] Dispenser

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact