What kind of Dispenser is there?

We have compiled answers to frequently asked questions. Please use it to solve basic information about Dispenser and questions about products and services.

For questions not listed below or more detailed inquiries, please feel free to contact us from this website.

What kind of Dispenser is there?

Types of Dispenser

Dispenser is broadly classified into a method that extrudes liquids by air pressure or pressure, a method that discharges materials with mechanical forces such as screws, and a method that utilizes contactless technologies such as jet methods.

These methods can be used differently depending on the liquid material to be handled, the object to be painted (work), and the required application conditions. In addition, even with the same liquid material, the optimal device may differ depending on the operating temperature range, discharge volume, curing speed, etc., so comprehensive consideration is essential when introducing it.

Musashi Engineering handles the following five types of Dispenser. Below are the characteristics of each Dispenser.

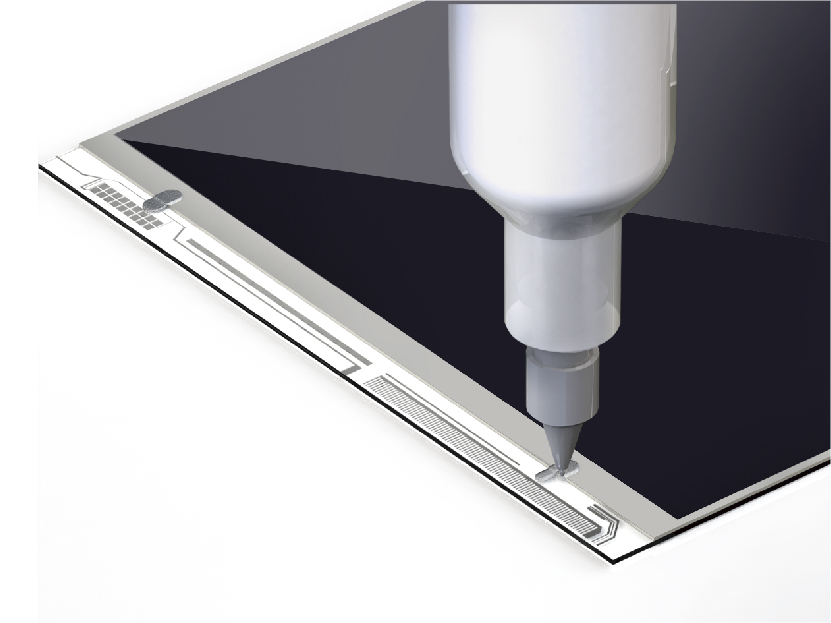

Air pulse method

This is a method in which highly controlled compressed air is added to plastic containers called syringes and barrels, and liquid materials are discharged from the Nozzle attached to the bottom of the container. While the application viscosity range is wide and easy to maintain, there are disadvantages in which the residual amount of liquid materials (water head difference) and changes in viscosity affect the discharge volume. We have developed and lineup high-performance Dispenser that overcome these disadvantages.

|

Ag paste application to touch panel

|

UV application to camera module

|

The highest peak of air pulse system

Full-function digital control Dispenser SuperΣCMIV

In addition to the automatic correction function for waterhead differences, it is equipped with a variety of functions that realize stable and high-precision application, such as prevention of liquid leakage and detection of liquid residual volume.

The excellent user interface with the touch panel allows you to intuitively grasp a lot of information and set it up more easily with the screen touch.

Energy-saving, cost-effective, and environmentally friendly design.

Recommended Links

>View the product information of SuperΣCMIV

>Air pulse Dispenser Product List

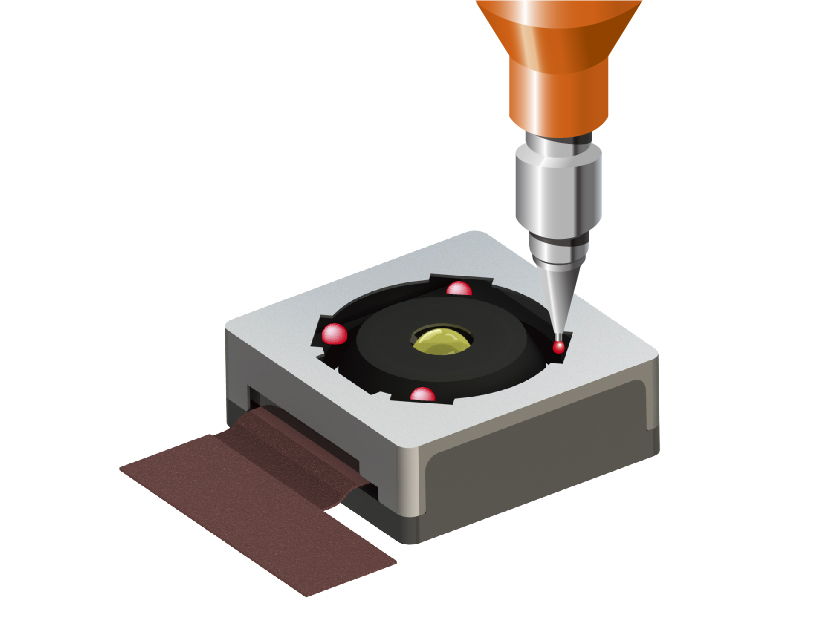

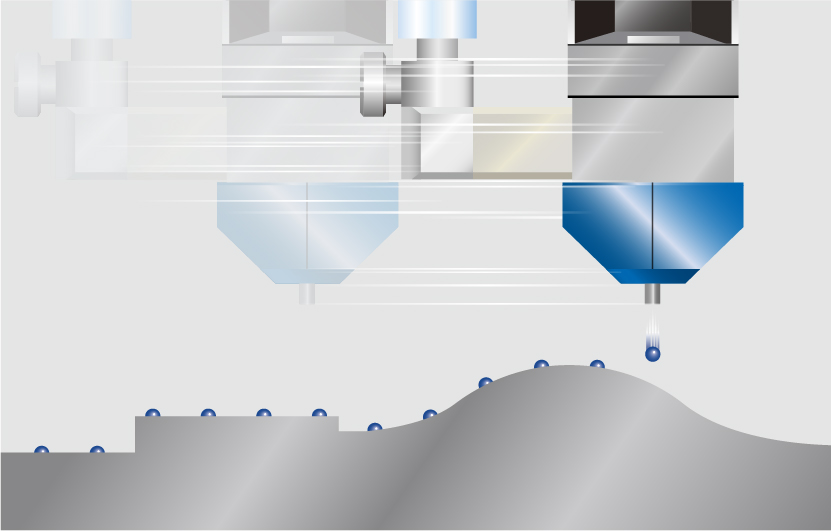

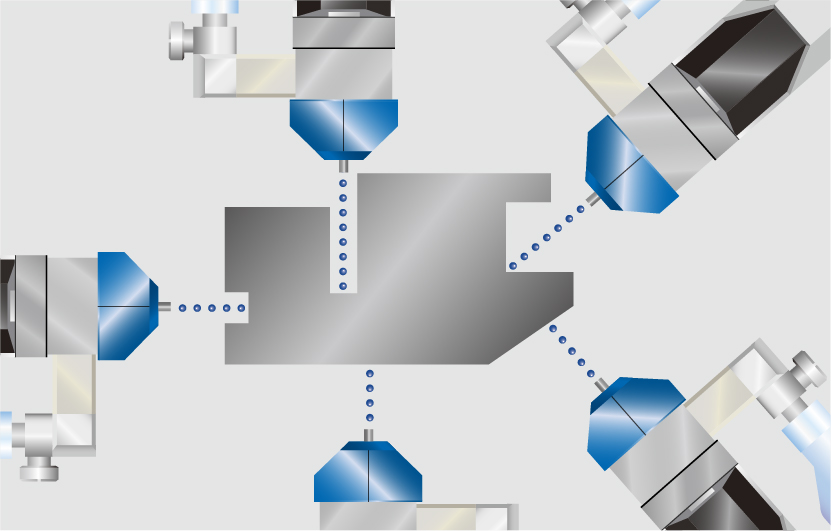

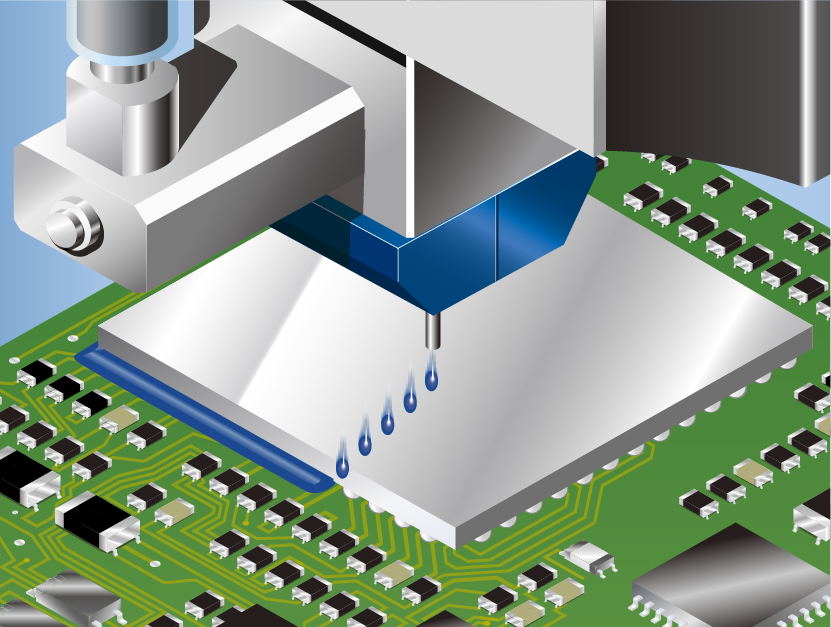

JET method

It is also called contactless Dispenser. This is a method in which liquid materials are "flyed" from the tip of the Nozzle, and the discharge speed is high, and there is no need for gap management between Nozzle and workpieces. Even on boards with many wiring and parts, there is no need to approach the application position of Nozzle, so it is possible to reduce the need for fine position adjustment so as not to damage the parts. It can be applied freely from the bottom, horizontal and diagonal directions.

|

|

Underfill agent application

|

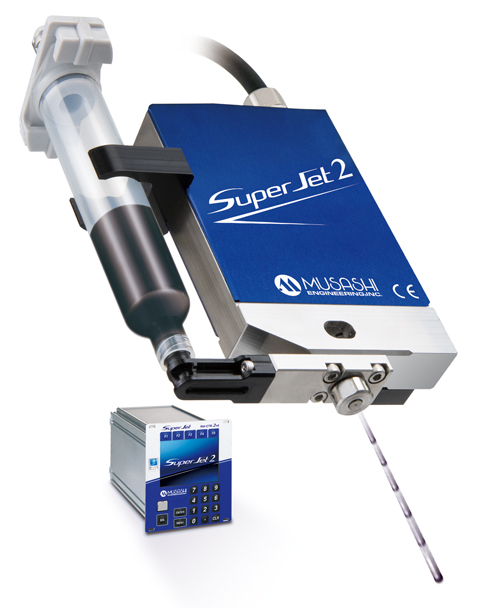

Pursuit of high reliability and high quality

"Ultra-high-speed and Non-contact JET dispenser SuperJet 2"

Jet Dispenser has not only achieved ultra-high speed and ultra-fine application but also improved convenience by reflecting customer feedback.

3 types of contact parts are available to accommodate syringes of all standards. In addition, there are various features such as rod replacement support.

Recommended Links

>View product information on SuperJet2

>JET Type Dispenser Product List

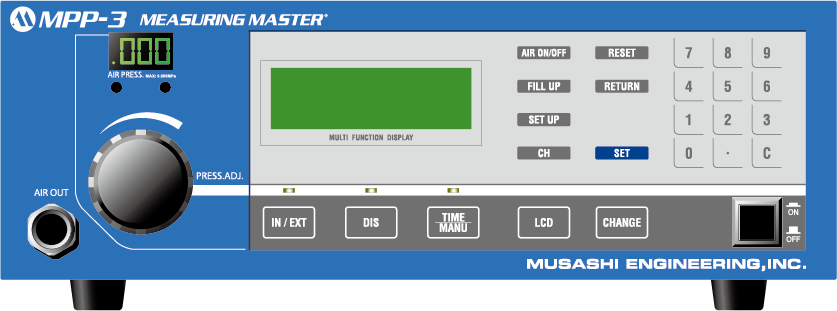

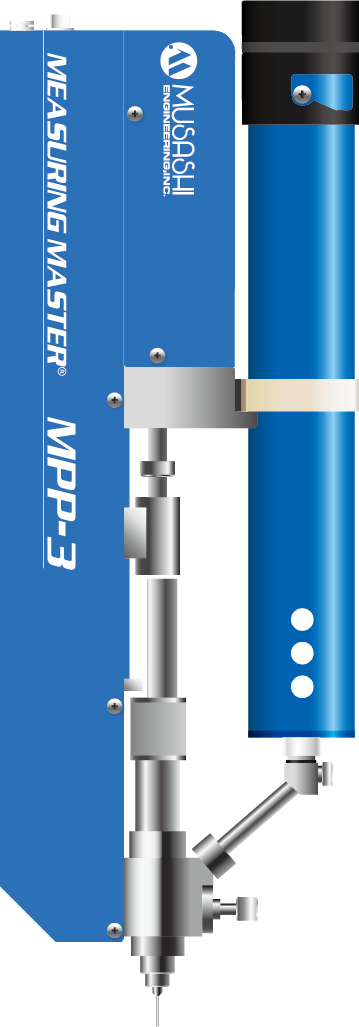

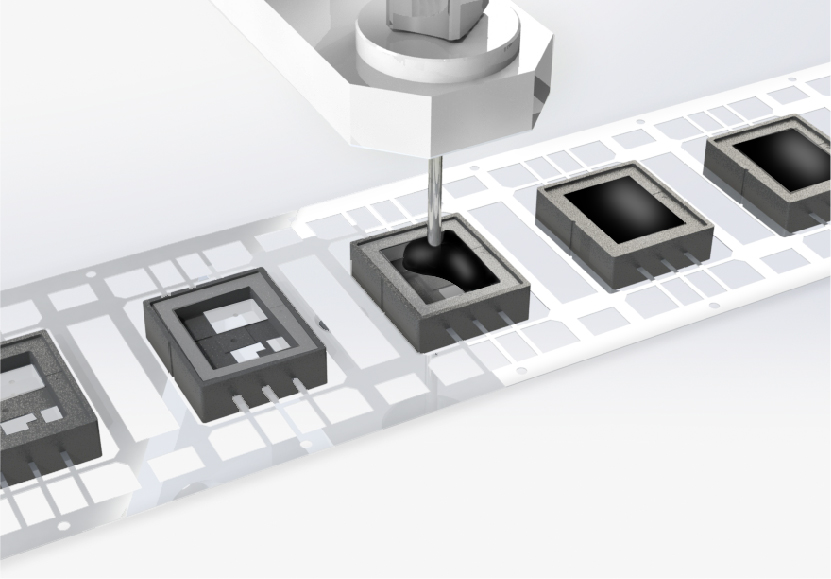

Volume measurement method

It is a method that controls and discharges liquid materials, such as plunger types and monotypes. The feature is that the discharge volume can be set by volume and mass. Because it is not affected by fluctuations in liquid viscosity and residual volume, it is possible to maintain a stable discharge volume, so this volumetric Dispenser is also used in semiconductor manufacturing and medical fields where precise application is important.

It is also used in situations where it is necessary to discharge a certain amount while maintaining the correct mixing ratio, such as applying 2-liquid materials (2-liquid mixing system).

|

|

Potting of sensor parts

|

Reagent Dispensing to vialbin

|

Exhalation of "viscosity-changing liquid" ultra-precision quantitatively!

Volumetric Digital Control Dispenser MEASURING MASTER MPP-5-S

Our unique plunger system has excellent durability. You can set the discharge volume by volume and weight, and you can check the surprising quantitative discharge accuracy from this video. In addition to MMP-5-S, MPP-5-M for large-capacity discharge is also available.

Our unique plunger system has excellent durability. You can set the discharge volume by volume and weight, and you can check the surprising quantitative discharge accuracy from this video. In addition to MMP-5-S, MPP-5-M for large-capacity discharge is also available.

Recommended Links

>Volume Measurement Method Dispenser Product List

>What is a plunger pump?

>Two component dispenser Product List

>What is 2-mixed Dispenser?

>View product information of MPP-5-S

>View product information of MPP-5-M

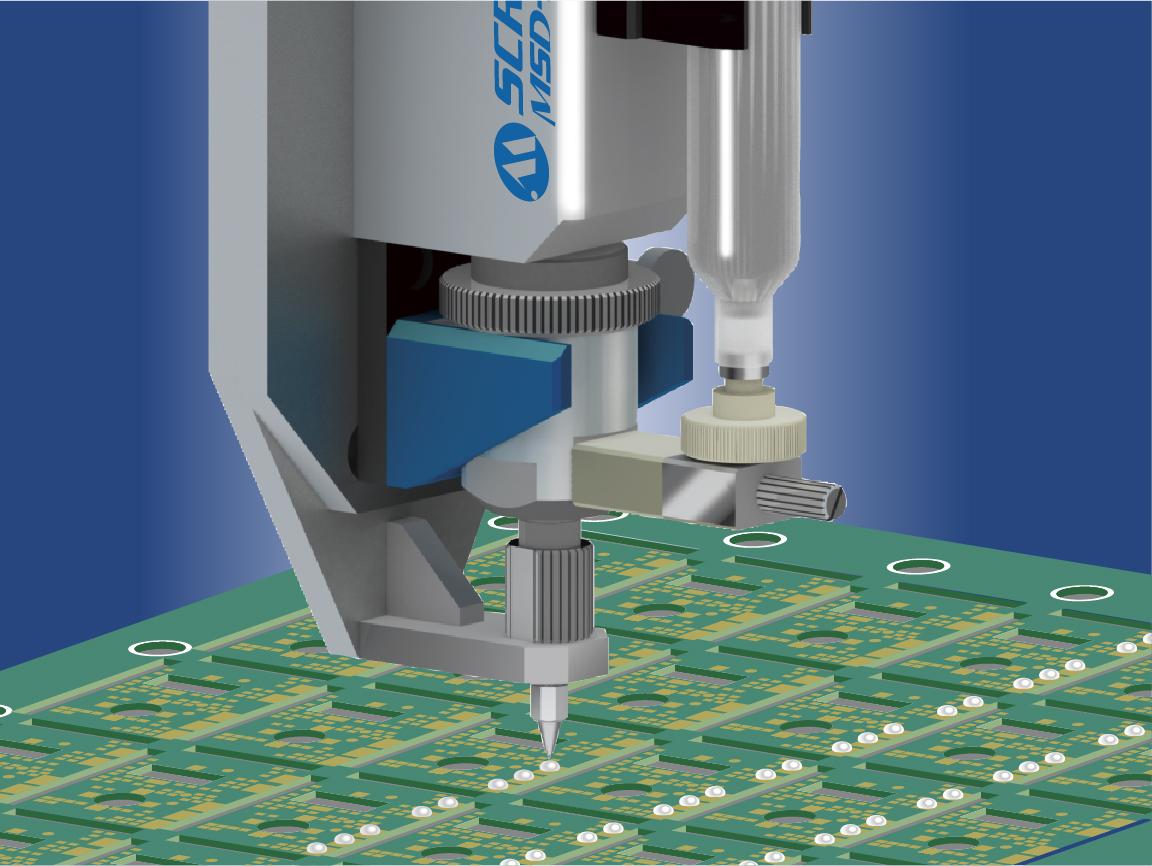

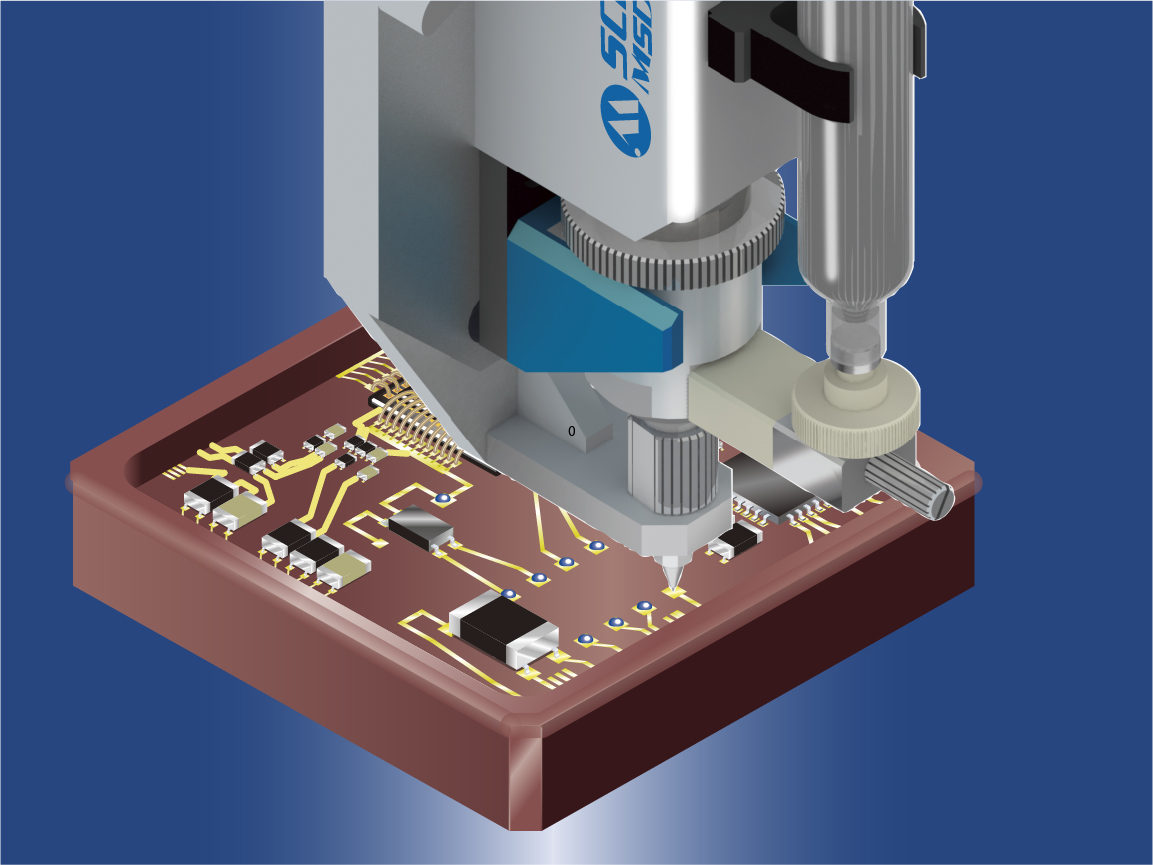

Screw method

This is a method in which a liquid material is extruded and discharged by rotating a screw-shaped rod. Due to its excellent propulsion, it is suitable for application of highly viscosity liquid materials such as Heat dissipation materials containing particles (fillers) and conductive adhesives. In addition, by controlling the rotation speed of the screw, it has the advantage that it is easy to keep the target discharge amount constant.

|

|

|

|

High-speed and stable application without clogging liquid with high viscosity filler!

"High performance screw Dispenser SCREW MASTER3"

Dispenser is suitable for liquid materials such as cream solder, epoxy resin, and Heat dissipation grease that are difficult to apply stably high speed and high precision.

In addition, it is a product with a variety of benefits, such as the convenience of easily replacing syringes, and the cost performance that uses up liquid materials to the end and reduces losses.

Recommended Links

>Screw Dispenser Product List

>View product information in SCRW MASTER3

Tubing method

This is a method in which the rotor attached to the rotating body sends fluid by crushing the tube continuously. ①It is used for the application of instant adhesives (cyanoacrylate) and anaerobic liquids (liquid that hardens when exposed to metal while the air is cut off), and low viscosity liquids (liquid that hardens when exposed to metal while the air is blocked), which does not use air pressure for liquids.

Ideal for applying trace amounts of anaerobic and low viscosity instant adhesives!

"Rotary Tubbing Dispenser MT-410"

Low viscosity liquid material also reduces the generation of liquids and bubbles. Dispenser is easy to set the tube and achieves high-precision application without troublesome adjustment. An optional discharge pen with remote switch for manual work is available, and it is a popular product in the manual application process.

Recommended Links

>View the product information of MT-410

>Manual dispense system

Recommended catalog

General catalog

Part Accessories & Valves/Tank Catalog

Fully automatic dispensing machine Catalog

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact