What is a plunger pump? Explain the structure, structure, characteristics, types, etc.

What is the mechanism of the plunger pump and the benefits of Dispenser?

Plunger pumps are important equipment used in many industries. Here, we will explain in detail the mechanism, type, application range, maintenance, etc. from the outline of the plunger pump.

What is a plunger pump?

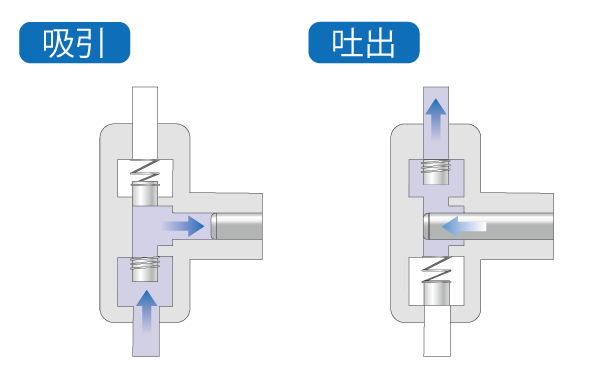

The plunger pump has a mechanism to quantitatively extrup liquid using a piston-shaped part called a plunger, and is a pump that can inspire and discharge liquids. It is used in a wide range of industrial applications such as chemical injection, oil transportation, and Food processing.

Structure and structure of plunger pumps

The plunger pump transports the liquid by the plunger round-trip motion inside the cylinder. When the plunger retreats, the liquid is suctioned (Filling) into the cylinder, and when moving forward, the liquid is discharged.

For example, a plunger pump used in a water treatment facility plays a role in pushing the water in the cylinder to high pressure by the plunger movement and sending it to the process of purifying sewage. The high pressure generated by the piston movement enables efficient liquid transfer and purification treatment.

Benefits of Plunger Pump

Plunger pumps are very accurate because they manage the discharge volume at the volume of the cylinder. Since the liquid is pushed out at high pressure, the discharge rate is also high. On the other hand, because it is a simple mechanism, it has the advantage that it is easy to maintain and durable.

◎ High discharge accuracy◎ Spilling speed is fast

◎ Easy maintenance

◎ High durability

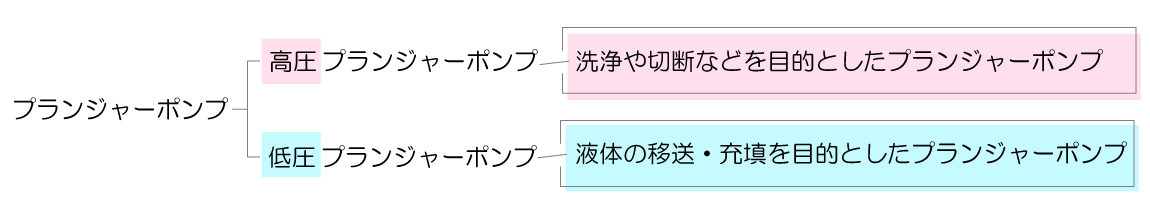

Types of plunger pumps

1) High pressure plunger pump

Plunger pump with a special structure that boosts pressure. High-pressure cleaning equipment and water cutting machines use high-pressure plunger pumps to generate strong water flow, remove dirt and cut hard materials such as metals.

2) Low pressure plunger pump

For high-pressure plunger pumps for functions such as cleaning and cutting, those used in processes aimed at supplying liquids are distinguished from low-pressure plunger pumps. Low pressure plunger pumps are suitable for cooling water supply systems and agricultural irrigation. The cooling water supply system supplies a large amount of water with a plunger pump for efficient cooling of industrial processes and large machinery. In agricultural irrigation, a large amount of water is supplied evenly with a plunger pump to water a wide range of fields.

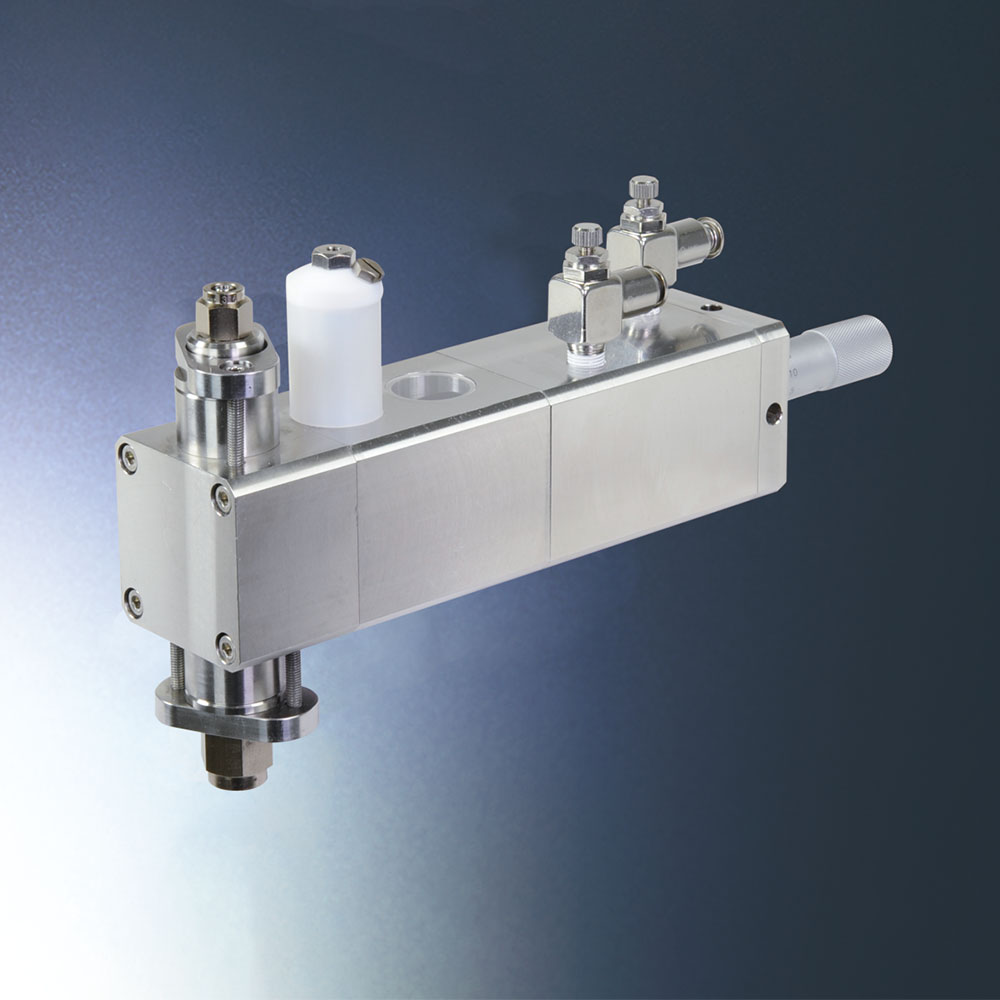

Planter pump of Musashi Engineering

We manufacture JUSTROPUMP, a low-pressure plunger pump for the quantitative discharge and supply of liquids. The Plunger Pump’s greatest features are quantification and high durability, which are used mainly in the food industry and in the Filling process in Industry electronic components.

・Precision and quantitative discharge of low viscosity liquid materials

・High-speed dispensing by high cycle speed.

How to choose a plunger pump

1) Confirm the liquid material and contact material

We propose the material of the pump body and the material of the O-ring according to the liquid material used. If you are concerned about chemical resistance, Please feel free to cuntact us.

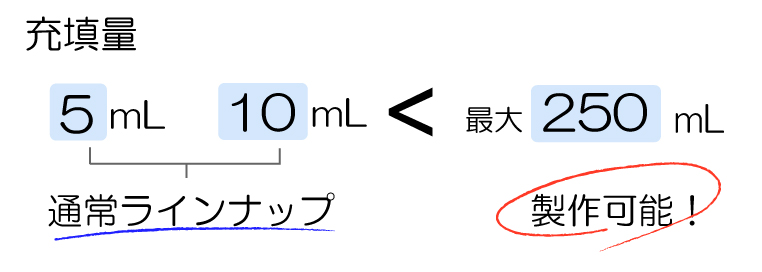

2) Check the amount of Filling

Check the minimum discharge amount and maximum discharge amount that you want to sow with one pump. The volume exceeding the capacity of the pump cannot be discharged in a single suction, but the larger the size of the pump, the harsher the resolution of the discharge. We have a lineup of two types, 5mL and 13mL, but we can manufacture up to 250mL sizes.

3) Select the drive method

The plunger drive method is the cheapest and most common air drive. The plunger operates by switching the air ON and OFF according to the timing of suction and discharge.

Reference) Dedicated pump controller ME-5000P

In the case of air drive, the amount of discharge and discharge speed are adjusted by opening and closing the micrometer or speed controller attached to the pump body. Therefore, if the Filling volume frequently changes depending on the application and variety, a motor-driven plunger pump is recommended that the volume in the pump can be controlled by the motor. We also sell motor-driven types on a custom order basis.

Air drive

The discharge volume and discharge speed are changed by operation of the pump body.

Motor drive

The amount of discharge and discharge speed can be controlled from the upper device.

Demerits of plunger pumps

1) Adaptable material viscosity range is narrow

The plunger pump is not suitable for transporting medium to high viscosity liquid materials because it absorbs the liquid at the negative pressure generated in the cylinder due to the movement of the plunger.

2) Can't control the speed of operation of the plunger

The speed of operation of the plunger affects the time of discharge. The air-driven plunger pump can be adjusted to shorten or lengthen the discharge time overall, but the speed of movement during the stroke from the start to the end of the plunger movement is not constant. Therefore, even though there is the quantitativeity of the liquid that the pump eventually vomits, it cannot be used for applications that discharge at a constant speed, such as Line dispensing.

3) Filling and discharge are always set once at a time

In principle, the accuracy of the plunger pump is not obtained unless it discharges all of the amount filled at one time in one time. It is not possible to stop halfway or change the amount of discharge along the way to discharge only half.

Plunger pump type Dispenser

Our Dispenser and MPP series apply the plunger pump mechanism to Dispenser to achieve excellent durability and high-precision discharge in response to changes in the viscosity of liquid materials. In addition, we have eliminated the disadvantages of the plunger pump mentioned above.

1) Adaptable material viscosity range

Due to pressurization on liquid materials, high viscosity materials that cannot be suctioned by ordinary plunger pumps can also be discharged from Filling. As a result, it can be used for quantitative discharge of liquid materials such as adhesives and greases.

2) The operating speed of the plunger can be controlled

The plunger is motor-driven, capable of discharge operation at a constant speed, so it can also be used for Line dispensing application and percussion application of adhesives. It is possible to manage the discharge rate optimally without changing the discharge amount.

3) Filling amount and discharge amount can be set separately

The amount of stroke (output) and speed of the motor can be stored up to 400CH, and the liquid material filled in one operation can be arbitrarily divided and discharged. As a result, it is possible to automatically apply multiple patterns to a single workpiece.

Our MPP series is a volumetric digital control Dispenser that accurately quantitatively discharges viscosity-changing liquid agents. The discharge volume can be set by volume and weight, and the unique plunger method boasts excellent durability.

The two lineups of MPP-5-S for precision application and MPP-5-M for large-capacity discharge contribute to the stability and improvement of application processes in a wide range of fields.

・The discharge volume can be set by volume and weight

・Excellent durability thanks to our unique plunger system

・10 times higher capacity volumetric digital Dispenser

・The head can be selected according to the lineup of pump size

Recommended catalog

MPP-5-S

MPP-5-M

JUSTRO PUMP