What is 2-mixed Dispenser? Explain basic knowledge of 2-mixed discharge device!

2 Fluid Mixed Dispenser

Also called "2-liquid Dispenser" or "2-liquid mixed discharge device", this device is a device that precisely mixes and discharges two liquids with different components. It has an advanced mechanism to maintain a uniform mixing ratio, and realizes efficient application work at manufacturing sites. 2-liquid mixture Dispenser plays an essential role in the manufacturing industry that requires application accuracy.

Basic principles and characteristics of 2-liquid mixture Dispenser

The basic principle of Dispenser is to mix two types of liquids in an accurate ratio and discharge them in a uniform state. Increasing the accuracy of the mixing ratio is very important in ensuring the performance of the two-liquid curing agent. If it is not properly mixed, product problems such as poor hardening may occur, but the 2-liquid Dispenser can prevent this risk beforehand. Furthermore, precision and accurate discharge by Dispenser ensures uniformity of materials and streamlines manufacturing processes.

Supported materials and their main applications

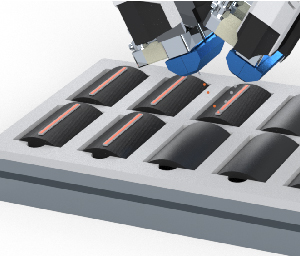

2 Fluids applied in Dispenser include epoxy adhesives and urethane sealants. These two liquids are used in applications that require high adhesion strength and flexibility.

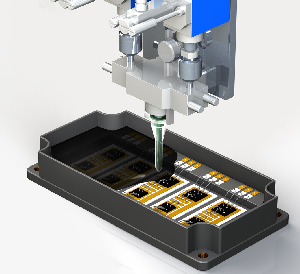

Epoxy resin is used for sealing electronic components and protection of substrates due to its electrical insulation properties, and urethane resin can be applied to cushions and sealed parts by taking advantage of its high flexibility. These are used in car electronics, smartphones, and architectural fields, as well as in bonding with high strength and weather resistance, as well as sealing of electronic components and substrates.

Mixing process and role of Dispenser mixer

The 2-liquid mixing process consists of the supply and mixing of 2-liquid agents. Dispenser is responsible for accurate material supply and discharge, and the mixer allows for efficient and consistent mixing.

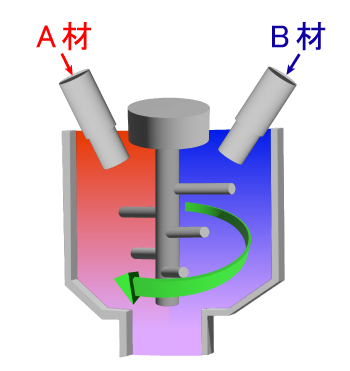

Precision liquid mixing with a high-precision mixing process achieves the performance according to the specifications of the two-liquid solution. The mixer has a static mixer (static mixer) and a rotary mixer (picture). By combining Dispenser and mixers, it is possible to meet a variety of working conditions and materials, and this technology is widely adopted throughout the industry.

The static mixer consists mainly of parts of special shape attached to the tube. When a fluid passes through a pipe, this part mixes uniformly by playing a role of mixing by dividing the fluid flow or changing the direction.

The static mixer consists mainly of parts of special shape attached to the tube. When a fluid passes through a pipe, this part mixes uniformly by playing a role of mixing by dividing the fluid flow or changing the direction.

It can be mixed without using electricity, and there is no moving part in the part, so it is not broken and easy to maintain.

The rotary mixer contains "screw-like" parts and feathers in an elongated cylinder, and the two liquids are stirred by rotating them at an appropriate speed according to the liquid. As an image, it is like the machine is automatically doing the work of mixing mixed juices with a muddler.

The rotary mixer contains "screw-like" parts and feathers in an elongated cylinder, and the two liquids are stirred by rotating them at an appropriate speed according to the liquid. As an image, it is like the machine is automatically doing the work of mixing mixed juices with a muddler.

By changing the rotation speed of the motor, the strength of mixing can be controlled to some extent, so it is possible to adjust such as allowing high-viscosity liquid materials to be mixed firmly and suppressing the generation of bubbles.

Consideration of options and processes required for introduction of Dispenser

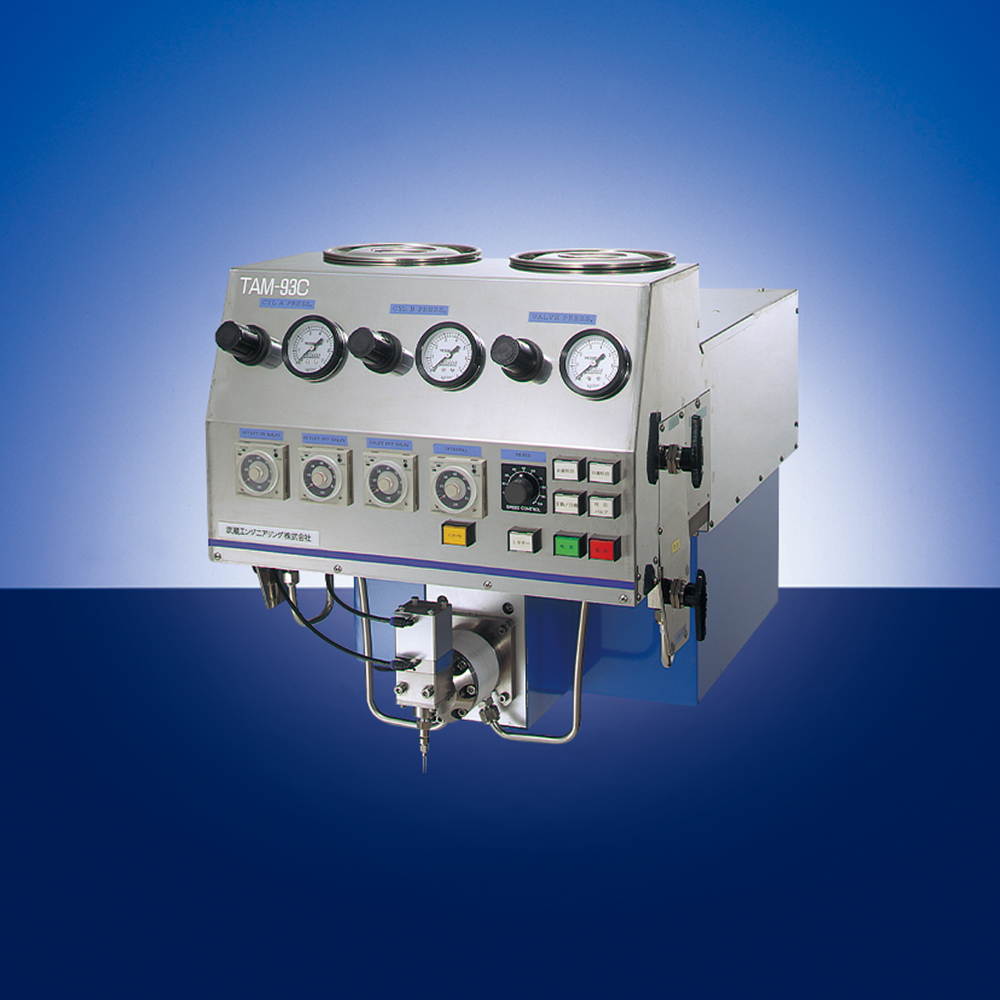

2 In the process of mixing and applying liquids, various options such as the aforementioned Dispenser mixer, tanks, scalers, and defoamers may be required.

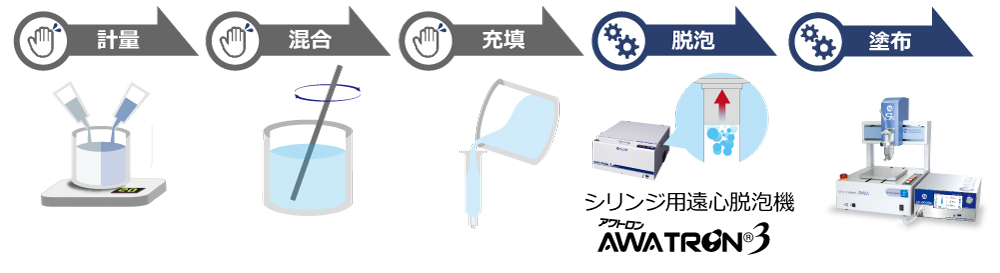

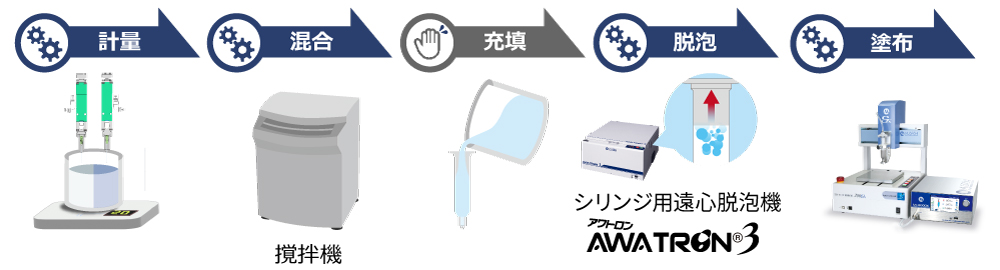

The following is an example of the process leading to application, but there are cases where Dispenser is introduced on the premise of manual processes or products are adopted for full automation. It is important to carefully consider the products according to the procedures and costs you want to achieve.

※Musashi Engineering also handles defoamers.

Mixing by hand to manage the amount of application in Dispenser

"Automated weighing and mixing", manually filling and managing the amount of application in Dispenser

No preparation for "Measurement / Mixing / Filling / Defoaming"!

Musashi Engineering's two-solid system that can be applied immediately

Type and characteristics of 2-liquid mixture Dispenser

2-liquid mixing Dispenser has different types, each with characteristics and advantages. Musashi Engineering offers the following three types:

Static mixer

- Volume measurement method

The volumetric pump enables strict management of mixing ratios and high-precision discharge. The amount of discharge can be set freely by volume and weight. High viscosity liquid can also be discharged.

- MOHNO Type

Continuous discharge is possible, mixing ratio can be set arbitrarily. In addition, it is possible to select the contact parts according to the characteristics of the liquid agent.

Rotary mixer

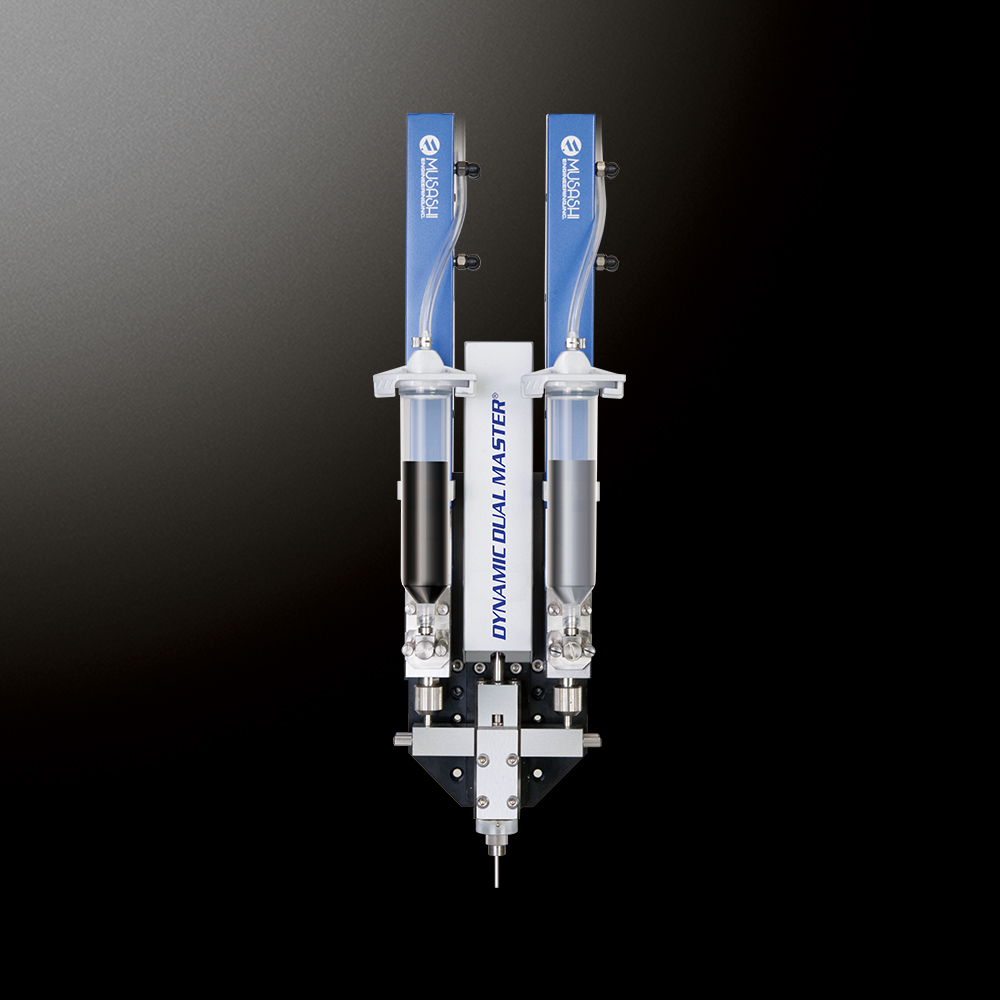

- Dynamic mixing method

This mixing method is suitable for materials with large differences in viscosity and mixing ratio. The mixing ratio can be set by volume and weight.

JET method

- This type does not require a mixing part (mixer). Recommended when using a reactive 2-liquid adhesive.

2-mixed Dispenser selection point

2 When choosing a mixture of liquid Dispenser, it is important to fully understand the structure and structure of the product by focusing on application specifications such as discharge speed, discharge volume and shape, as well as suitability based on its application and materials used. When choosing a product or deciding specifications, we recommend that you consult with a trusted dispenser manufacturer or professional engineer to try out the actual product demo.

Musashi Engineering has a track record of introduction in various fields and Industry, as well as testing applications and lending demonstration machines. If you are considering introducing a 2-mixed Dispenser or solving problems in the current work process, please visit Please feel free to cuntact us..

Recommended catalog

2 Liquid Dispense Solution

DUAL MPP-5-M-GF-MINI

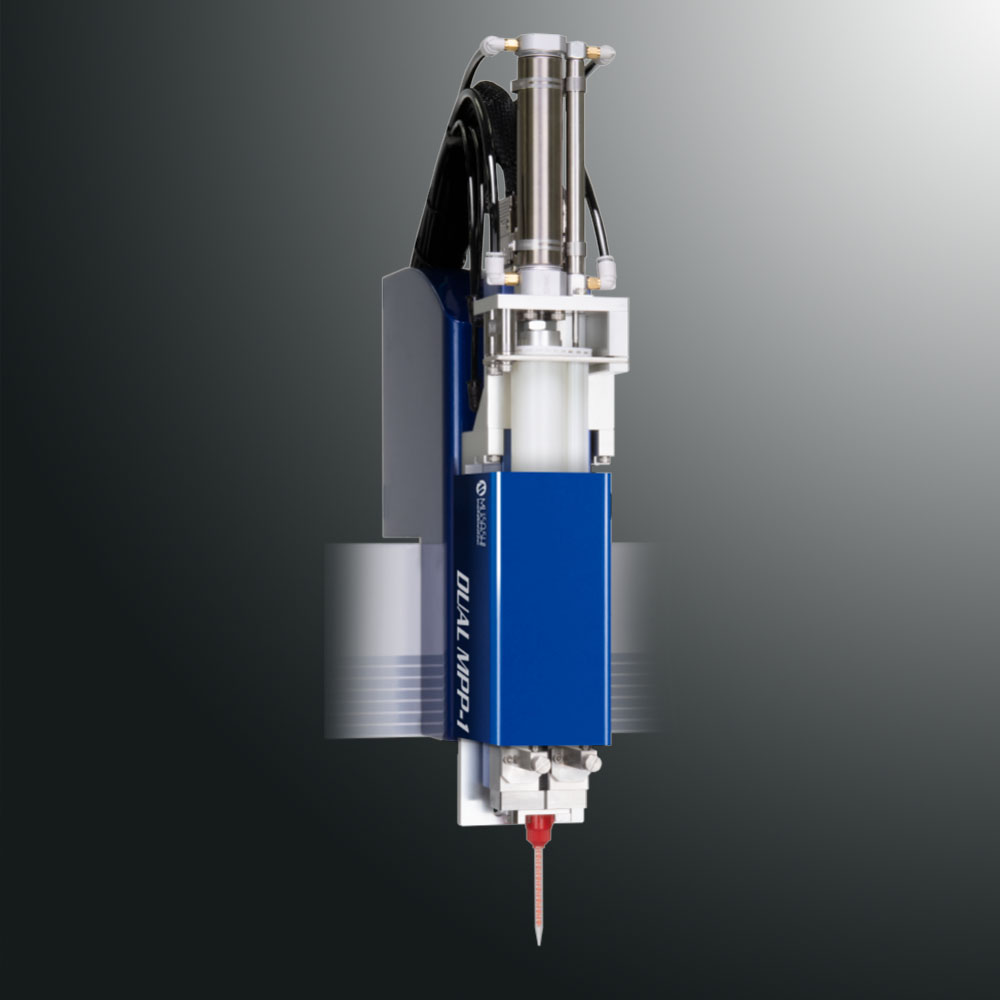

Dual MPP-1

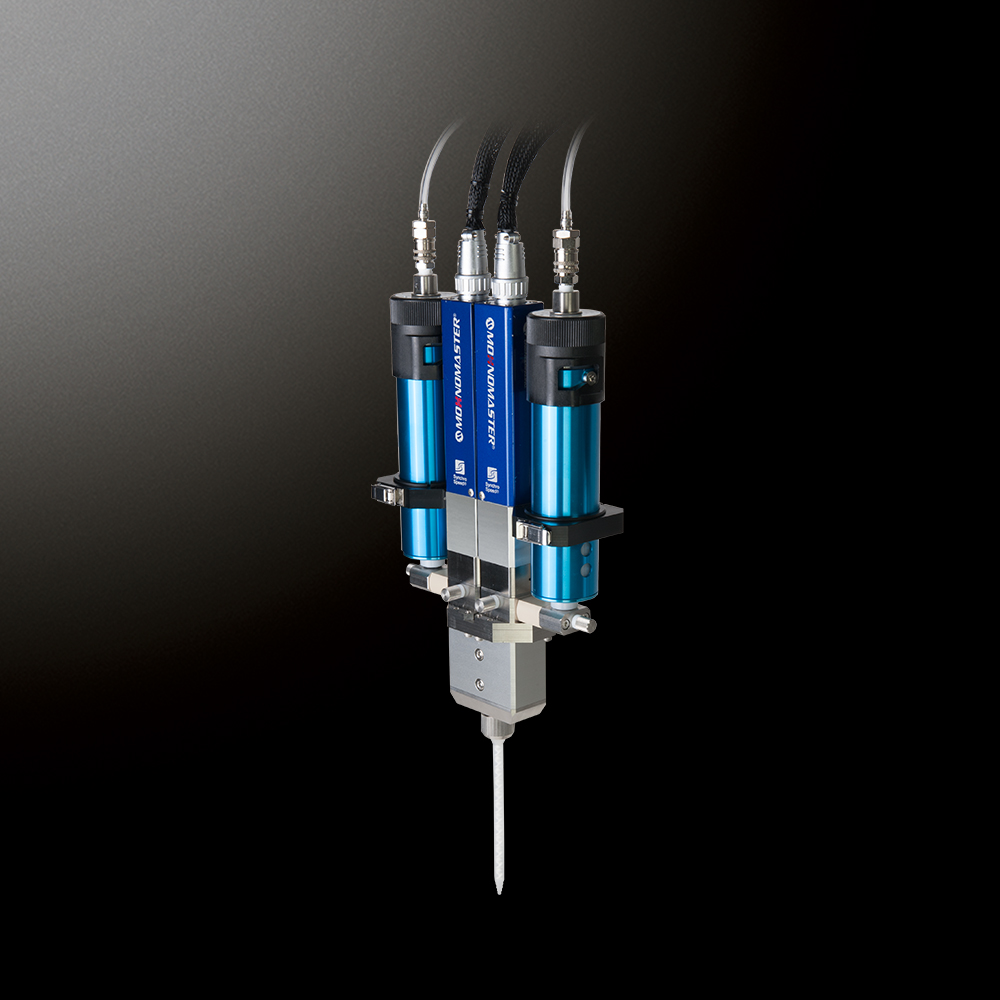

DYNAMIC DUAL MASTER