What is a conformal coating? Explain the knowledge necessary for application!

What is a conformal coating?

Conformal coating refers to uniformly and thin application of polymer or silicone coating materials to the surface of electronic components (mainly mounted substrates). This coating agent has excellent adhesion to details and unevenness, and can protect the substrate from moisture that leads to product defects. In addition, there are materials with heat resistance and medication resistance.

Taking advantage of its characteristics, conformal coatings are widely used in the automotive industry, such as automotive substrates and electronic control units for automobiles. In particular, components outside the engine room and vehicle body are subject to severe conditions such as high temperatures, high humidity, and vibration, so conformal coating is an indispensable process for improving the reliability and durability of parts and reducing the risk of failure.

Application technology for conformal coating

Low viscosity coating material application

Spot coating

Many conformal coating materials are insulating and colored, so they may not be attached to mounting parts such as connector sockets and optical systems. We call "spot coating" to apply the necessary amount of coating agent to where necessary while avoiding such parts. If spot coating is not possible, masking is performed in advance on the area where the application is prohibited, and then the entire surface is applied. However, since the removal of masking is manual, there is a problem in mass production.

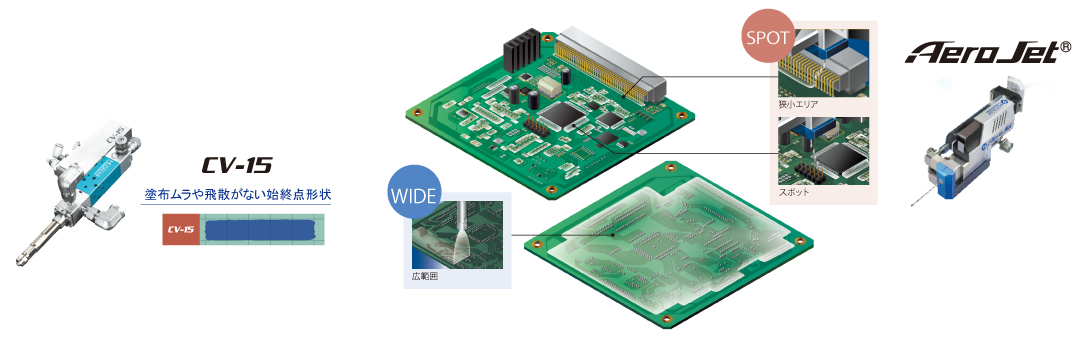

For spot coatings, there are also application methods for spraying liquids with needles and brush coatings, but at present, jet-type Dispenser is often used to cope with subtle irregularities of the mounting part and application to a narrow range.

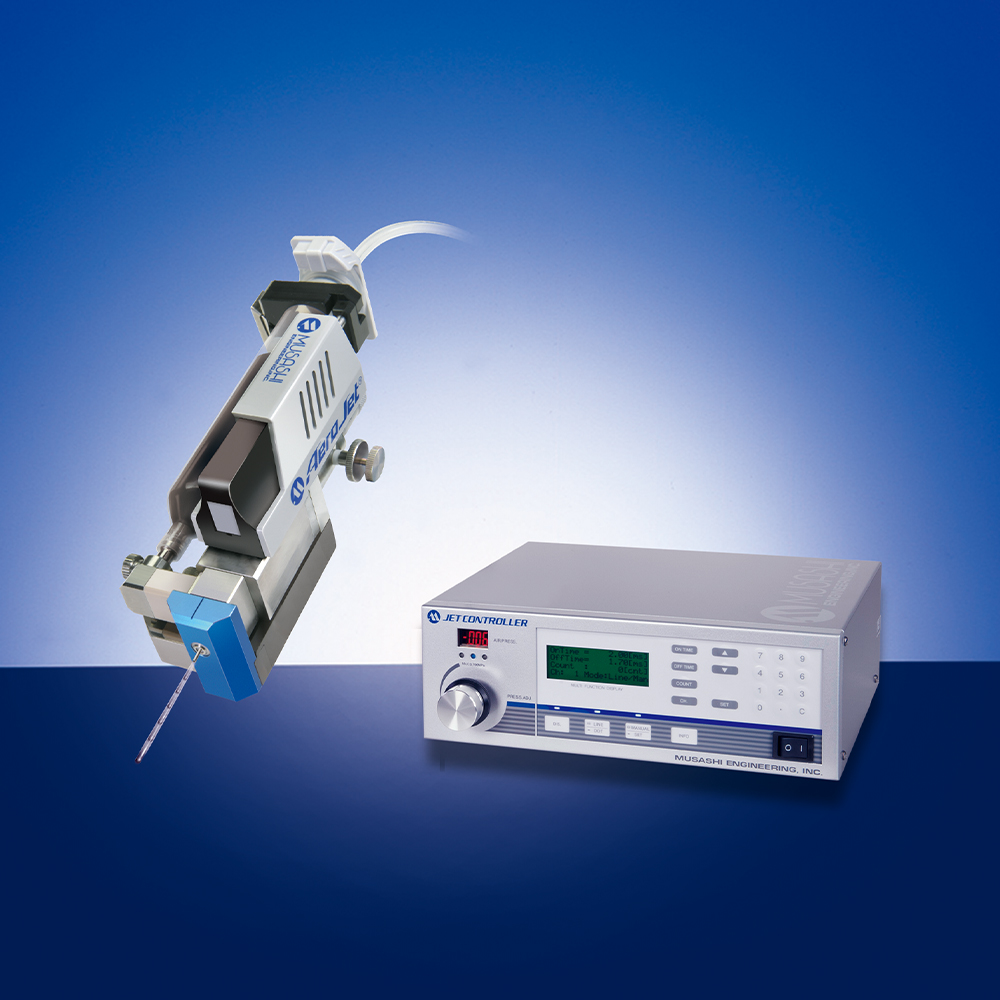

Jet type Dispenser "AeroJet"

Our Dispenser “AeroJet” jet system is capable of expelling liquids vigorously and flying from the tip of Nozzle. We also have a lineup of long Nozzles of 5mm to 30mm or more for coating substrates, which can be applied in narrow areas where Dispenser and mounting parts are easily interfered.

Wide coating

In contrast to spot coatings, we call "wide coatings" a method of applying a wide range at high speed. In wide coatings, curtain coats (also called film coats), which can be spread out and applied in a fan shape, are often used to prevent coating agents from scattering. At the end of 2023, we released the latest curtain coat valve "CV-15". This valve provides a cleaner and more stable application shape, with a three-fold increase in open and close responsiveness compared to conventional machines.

Anti-foaming coating

In particular, for solvent-type conformal coatings with low viscosity, it is important to prevent air bubbles. If the coating agent after application contains bubbles, it may cause condensation from there, leading to a failure of the substrate. The following three factors are the main factors for the contamination of bubbles.

- When air is involved from the tip of Dispenser

- When bubbles are dissolved in the coating agent itself in the supply container

- If the coating agent does not get wet and spread well

These measures include the management of equipment parameters, the method of installing an inner lid in the container, and the method of modifying the surface of substrates and parts before coating by plasma processing.

High viscosity coating material application

In recent years, especially in Europe, efforts to reduce VOCs and eliminate solvent-free conformal coatings have been accelerating. As a result, high viscosity coatings that do not contain solvents have increased as an option. The use of high-viscosity materials has the advantage of being able to move on to the next work without worrying about the fluid flow after application, and that it is difficult for liquids to flow into unnecessary areas.

Spot coating

The jet-type Dispenser, which is used in coatings with low viscosity materials, is also used for automatic application of grease and adhesives. In many cases, medium to high viscosity coatings can be applied without any special treatment.

Wide coating

If you want to apply a wide range of coatings, there is a significant difference in the application method that you should choose between low viscosity materials and high viscosity materials. The curtain coat valve described above is applied by spreading the liquid at the shape of the Nozzle and a constant flow velocity, but cannot be used for materials with high viscosity that are less likely to flow velocity.

We have released the "SSV-1" spray valve for high viscosity. This product is equipped with a technology for mixing liquids and gases to atomize, so that even high-viscosity liquids that could not be applied with conventional coating valves can be applied thinly and widely.

Conformal coating application equipment

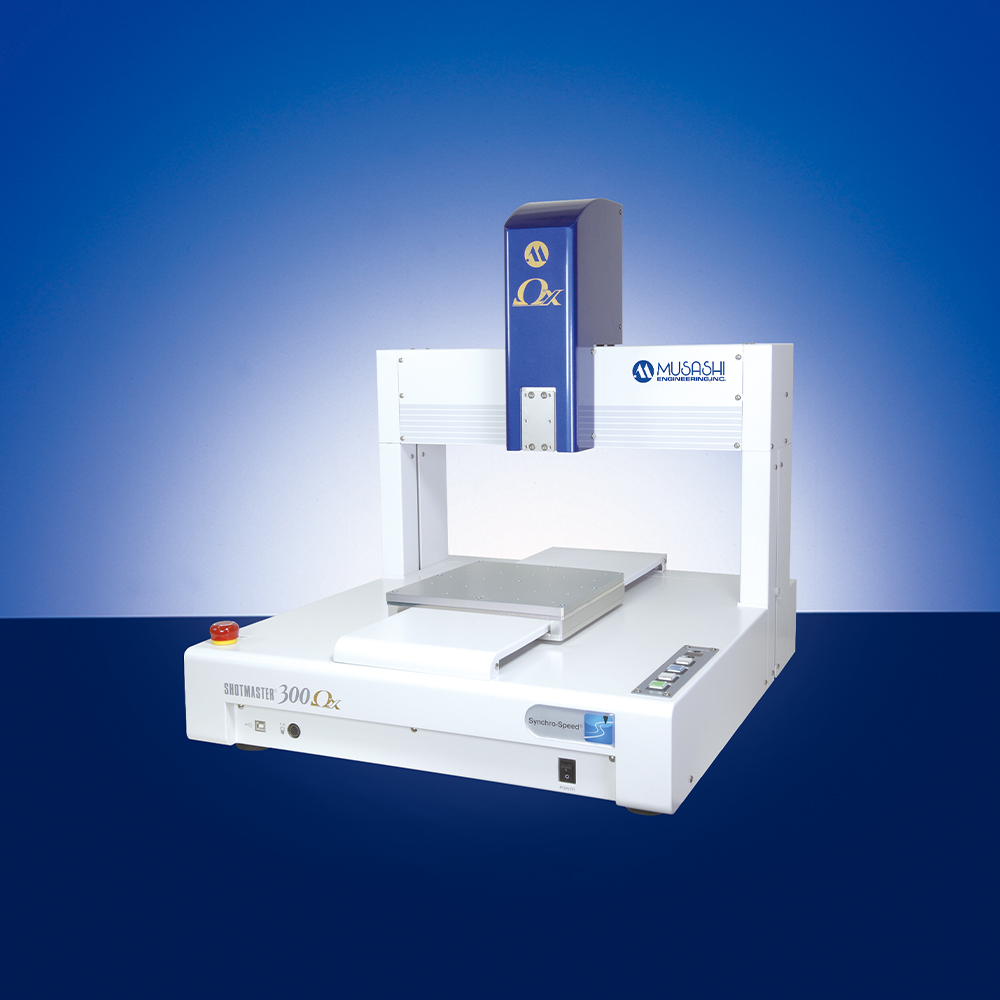

Semi-automatic coating equipment

We classify equipment that automates the application operation, but intervenes human intervention in some processes as "semi-automatic type". One of our representative products is the Desktop robot SHOTMASTER series, which can control XYZ 3 axis. This series does not correspond to industrial robots, and is characterized by its ease of installation on the desk and start operation on the same day. It is especially effective in the production of small and large varietys.

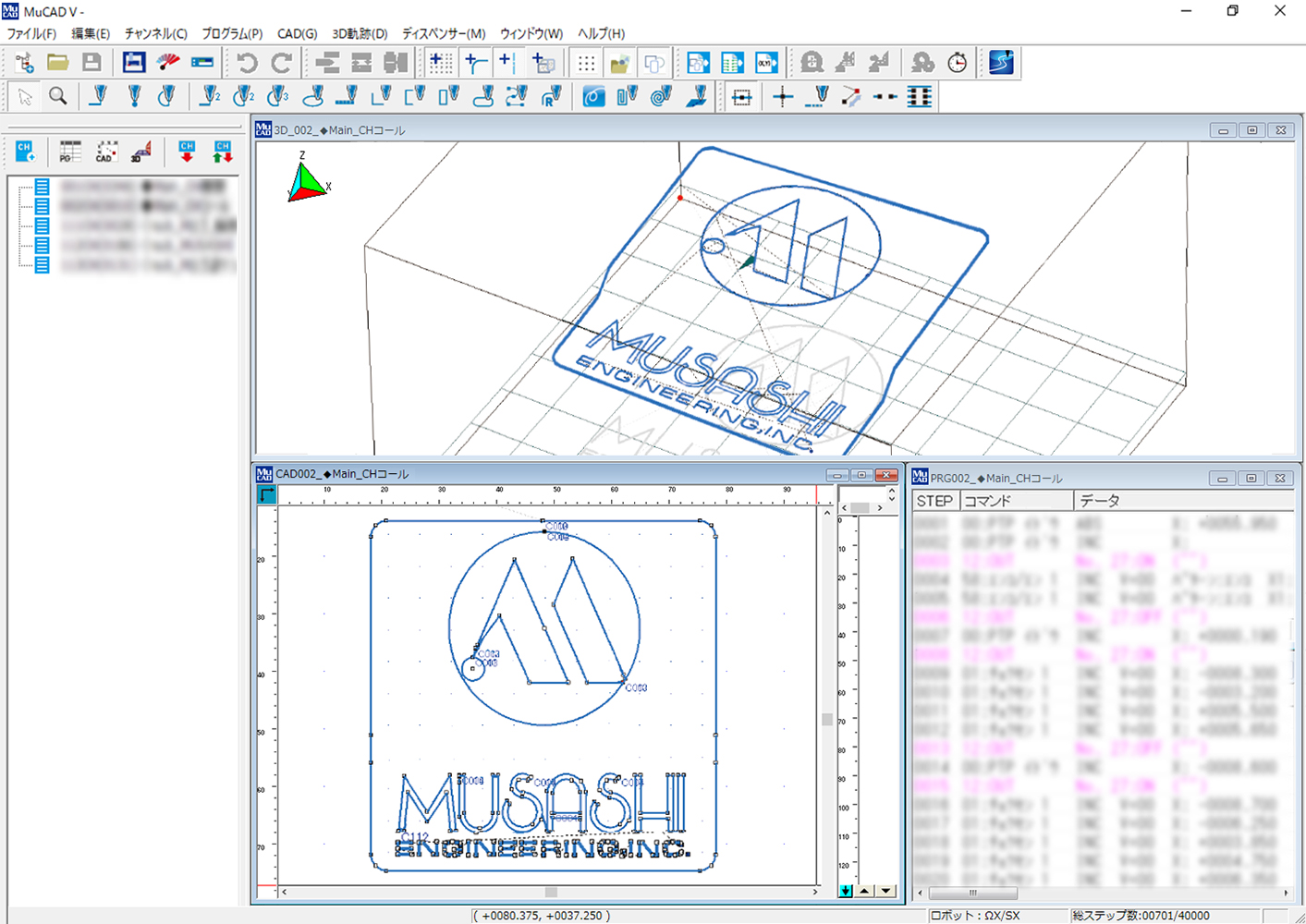

In addition, the dedicated program editing software "MuCADV" can easily create a program by incorporating the photo of the board and CAD data into the background of the program editing screen, superimposing it from above and specifying the application range by mouse operation. This software has an "intermediate cut function" that allows users to easily set the range that does not apply by specifying the application prohibited area during a series of application operations, and has received high praise from customers.

Fully automatic coating equipment

While semi-automatic devices are inexpensive and have excellent freedom and responsiveness, the fully automatic type is an application facility that integrates transport mechanisms to improve production capacity and quality. The FCD series of fully automated coating equipment features the following three key functions to increase yields through automatic application.

- Fluid temperature management system

Management of liquid temperature is very important for high-quality coatings. Stable fluid temperature is an important parameter to keep the amount and width of the application constant, and it also affects the wet spread after application. The FCD series is equipped with a system that circulates liquids as standard, and a dedicated temperature feedback mechanism maintains the liquid temperature constant and achieves high application quality. - Automatic correction of curtain width

Even if you manage the application conditions consistently with an excellent system, it is not easy to maintain the same application quality at all times. Therefore, the fully automatic coating device is equipped with a function to automatically correct the coating width with a dedicated monitoring system so that uniform application can be performed continuously. - Automatic correction of application position

It is also a requirement for high-quality application to move the robot to an accurate position on the substrate and apply it. In addition to recognizing the actual mark with the camera, correcting the position of the substrate and the inclination, the position of the liquid agent applied from the coating valve is automatically recognized with the camera, and the program is corrected to ensure the application is applied to the target point.

Coating equipment for large parts

In recent years, with the development of IoT and AI, the number of high-performance and large-scale mounting parts that perform information processing at high speed has been increasing. Due to the size of such parts and the diversification of functions required for a single substrate, the substrate itself tends to become larger. For coatings on large parts, it may be difficult to coat the base of the tall parts, but we offer products and options that address these challenges.

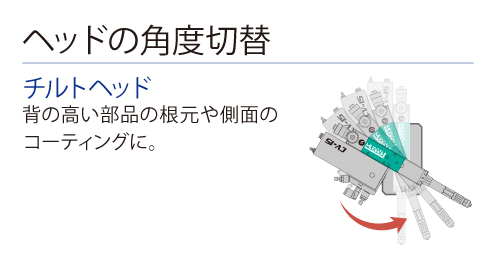

FCD1200 is a new product that expands the range of L-size substrates (up to 500mm x 500mm), which could not be transported by conventional machines. The board height that can be transported can be accommodated up to 90 mm on both front and back, including mounting parts, and the design is designed for coating on large parts. In both full and semi-automatic motions, the tilt head (Dispenser angle switching) mechanism can be selected as an option, and it is also compatible with difficult-to-access applications where Dispenser interferes with parts when approaching Nozzle from directly above.

Inquiries and Recommended Catalogs

We aim to contribute to solving problems at production sites through liquid precision control and application technologies such as coating technology. If you have any questions or inquiries regarding our application technology, please feel free to contact us.

Recommended catalog

Substrate coating

Solution

AeroJet

CV-15

FSV / SSV

FCD1200