Improve the discharge accuracy with a temperature controller! What is the role of warmth in Dispenser?

About this article

In this article, we will explain the effects of the temperature controller on the discharge of liquids, the features of the heating and Peltier heat tone, and the selection points.- What can you do with a temperature controller?

- Features of heating type temperature tone

- Features of Peltier-type temperature

- ①Maintaining a constant temperature of the liquid agent improves the discharge accuracy.

- ②Controls the temperature of the liquid agent lower than the environmental temperature and suppresses the change in the condition of the liquid agent.

- Demerits of Peltier-type temperature control

- Benefits of Peltier Temperature

- Musashi Engineering's Peltier-style temperature control

- Dispenser, Peltier Temperature Integrated Air Pulse System of Musashi Engineering

- If you want to minimize the impact of the change in viscosity of liquid agents

- Points of Product Selection

- Recommended catalog

Improve the discharge accuracy with a temperature controller! What is the role of warmth in Dispenser?

The equipment that regulates the temperature of the liquid agent is expressed in various expressions such as heating system, temperature control system, temperature control system, heat control system, and heat control system. We will explain what role this temperature controller plays.

Temperature connection system configuration diagram

What can you do with a temperature controller?

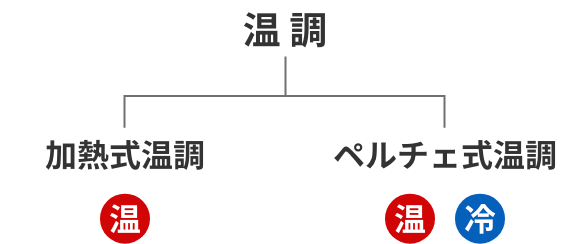

First of all, our temperature controllers are broadly divided into "heat type temperature" and "Peltier type temperature".

"Heated temperature control" is used to increase the temperature of the liquid agent. On the other hand, "Peltier temperature control" can be both increased or lowered, so it is used to maintain liquids at the desired temperature.

The Peltier system

The Perche element has the property of cooling one side (heat absorption) and heating the other side (Perche effect) when the current flows. Taking advantage of this characteristic, the method of cooling and heating around the syringe is called the Peltier-type temperature tone. In particular, when cooling syringes, fans and air are used because the heat generated on the other side needs to be effectively dissipated.

Features of heating type temperature tone

The main purpose of using heated temperature control is the following two.

①Reduces the viscosity of the liquid agent and improves the vomitability

②Eliminate discharge problems due to low environmental temperature

➀Reduces the viscosity of the liquid agent and improves the vomitability

When expelling liquids with high viscosity, it may take some time to discharge them as they are, or it may not be possible to apply with the desired amount or shape. Heated temperature tone can effectively reduce the viscosity by properly warming the liquid agent, making it easier to discharge.

In many cases, viscosity is also related to "treading" that is likely to occur when discharging liquids. If the viscosity is too high, the liquid agent is less likely to break when the discharge is finished, and it is more likely to occur that thin threads are pulled. By adjusting the viscosity appropriately by heating, this threading can be suppressed and the risk of defective occurrence in the post-process can be reduced.

②Eliminate discharge problems due to low environmental temperature

“We were able to discharge without problems in the test environment, but for some reason it doesn’t work at the actual manufacturing site.…"There are many cases in which environmental temperature has a significant effect on the background of such problems. In particular, when the environmental temperature at the site is low, such as in winter or cold regions, the viscosity of the liquid agent increases.

By introducing a heated temperature control system, it is possible to keep liquids at a constant temperature without being affected by the environmental temperature of the site. As a result, it maintains stable discharge performance regardless of season or place, leading to improved productivity and quality stabilization.

Demerits of heating-type temperature control

- Fluids that are sensitive to heat may have a negative effect on heating

- Because it has no cooling function, it is not possible to lower the temperature of the liquid agent than the environmental temperature.

Benefits of heating-type temperature control

- Simple structure makes it easy to maintain and low risk of failure

- Relatively low cost of introduction

Heated temperature control of Musashi Engineering

Features of Peltier-type temperature

The biggest advantage of the Peltier temperature control system is that it has both "warm" and "cool" functions.

The main purpose of using Peltier temperature control is the following two.

①Maintaining a constant temperature of the liquid agent improves the discharge accuracy.

②Controls the temperature of the liquid agent lower than the environmental temperature and suppresses the change in the condition of the liquid agent.

①Maintaining a constant temperature of the liquid agent improves the discharge accuracy.

The room temperature at the manufacturing site always changes depending on the season, time of day, and availability of air conditioning equipment. This change in room temperature affects the temperature of the liquid agent itself and causes fluctuations in viscosity. For example, if the room temperature rises, the viscosity decreases, and the discharge volume may increase. Conversely, if the room temperature drops, the viscosity will increase and the discharge volume may decrease. In response to such changes in the external environment, the Peltier system allows for precise temperature maintenance in an integrated manner of heating and cooling.

In addition to the effects from the external environment, it is also effective against heat generation inside the syringe (e.g. chemical reaction heat of adhesives, etc.) is a major feature of Peltier-type temperature control with cooling functions.

②Controls the temperature of the liquid agent lower than the environmental temperature and suppresses the change in the condition of the liquid agent.

Demerits of Peltier-type temperature control

- Low cap of adjustable temperature range

Benefits of Peltier Temperature

- Precision temperature maintenance by integrated heating and cooling

Musashi Engineering's Peltier-style temperature control

The fan type can be used only on the power supply, but if you are concerned about the dust of the fan, such as in a clean room, please consider the air type Peltier heat control unit.

The TCU-05MINI is a new temperature controller that supports both fan and air blocks.

Dispenser, Peltier Temperature Integrated Air Pulse System of Musashi Engineering

The following temperature control integrated Dispenser has a built-in temperature control controller, allowing temperature control on the setting screen of Dispenser. (The temperature control block and the temperature control cable are sold separately)

Temperature connection system configuration diagram (Peltier type thermo-control integrated type)

Full-function digital control Dispenser SuperΣCMIV Pro

Higher-level models equipped with Σ 3 major functions and temperature control functions.

Air pulse system with built-in temperature control CTR Dispenser ML-7000X

Space for two cars is aggregated into one unit to save space. It is easy to set the discharge and temperature.

If you want to minimize the impact of the change in viscosity of liquid agents

Volume Weighing Type Dispenser MPP Series

We propose a volumetric Dispenser MPP series.

The MPP series is Dispenser, which is characterized by "quantification" that is less susceptible to changes in liquid viscosity.

Even if the "viscosity" of the liquid agent changes, the "crush" (volume)" to be exhaled is always kept constant, so it is possible to provide a stable and accurate amount.

In order to control the amount of discharge according to the amount of movement of the plunger, a certain amount of discharge is performed regardless of the liquid viscosity.

Utilization of MPP series: Responding to factors other than viscosity changes due to temperature

The cause of dissipation is not always limited to changes in viscosity due to temperature. For example, whenever a lot of liquids (manufacturing number) changes, there may be slight variations in liquids viscosity.

Examples of variations between liquid lots

Even in cases where the discharge volume increases or decreases due to such "variability between liquid lots", the MPP series, which accurately measures the volume of liquid agents, will be effective. It is not affected by the difference in liquid viscosity of each lot, but always emits a fixed volume set, so it is possible to maintain a stable discharge volume.

Demerits of the MPP series

- It takes Filling time for liquid agent at a certain time

Benefits of MPP Series

- It is less susceptible to both changes in the viscosity of the liquid agent and the variation in the viscosity between the liquid lot.

- Suitable for a wide range of viscosity liquids

- High discharge stability

Musashi Engineering's volumetric Dispenser MPP series

Points of Product Selection

When selecting products, it is important to consider the following points. In light of these, you need to choose the best product.

- Characteristics of liquid agent: Consider the viscosity of the liquid agent used, the effect of temperature changes, and the effect of heating and cooling on the liquid agent.

- Installation environment: Consider changes in room temperature, operating heat generated from the device, space in the installation location, etc.

- Production Line Requirements: Consider the required discharge accuracy, stability of quantity, constraint of the container used, etc.

- Cost side: Consider initial installation costs, running costs for operation, ease and frequency of daily maintenance, etc.

It is important to comprehensively judge these factors and select products that are optimal for the application and environment.

Resolve discharge problems with dispense solutions from Musashi Engineering

Issues such as "instability of discharge volume", "variance of quality" and "maintenance load" in the discharge process of liquid agents are important issues directly related to production efficiency and product quality.

We propose the best solution according to your specific situation, from changes in liquid viscosity, environmental temperature effects, variation between liquid lot, and demand for advanced discharge accuracy.

We will respond flexibly to the diverse needs of our customers with a variety of product lineups, so if you have any problems with discharging or applying liquids, please contact us once.

Recommended catalog

Peripherals and Accessories

Heated temperature control / Peltier temperature control

PELTIER MASTER

THERMO MASTER

Dispenser

Peltier Temperature Integrated Air Pulse System Dispenser

SuperΣCMⅣ Pro

ML-7000X

Volume Weighing Type Dispenser MPP Series

MPP-5-S

MPP-5-M