Air pulse Dispenser Challenges and Solutions! Σ 3 major functions that solve the problem of application

There are many challenges in handling liquids at production sites. Problems encountered during the production process can sometimes have a significant impact on work efficiency and quality. In this article, we will introduce the Σ 3 major functions developed to prevent these problems and achieve efficient production.

What is Σ3 major functions?

The Σ3 major feature is an important technology for precision application of the air pulse Dispenser installed in the SuperΣ series. Specifically, it refers to the following three functions.

- 1. Automatic waterhead difference correction function

- 2. Automatic liquid leak prevention function

- 3. Automatic residual volume warning function

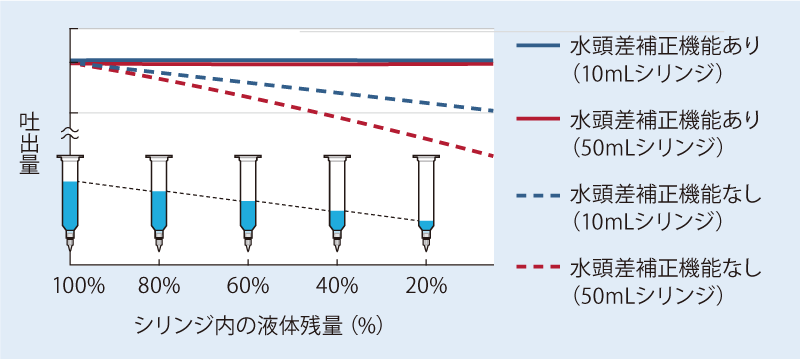

1.Water head difference automatic correction function

When the liquid in the syringe decreases, the height of the liquid surface inside becomes low. This reduction in height reduces the force (pressure force) on the liquid, resulting in a decrease in the discharge volume.

▼

The waterhead difference automatic correction function detects changes in the waterhead, automatically detects the position of the waterhead, and adjusts the discharge amount according to the results. If this function is not available, the discharge volume will decrease as shown in the graph below, making it difficult to apply with high accuracy.

The water head differential automatic correction function always maintains a constant discharge volume and allows for high-precision application.

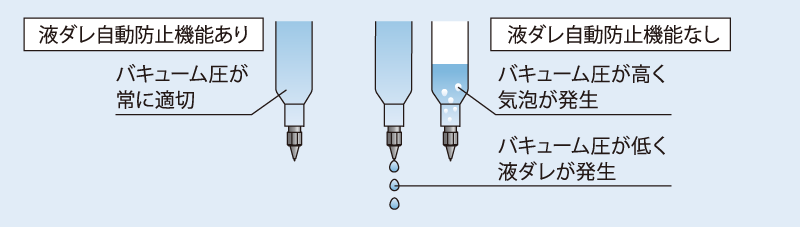

2.Liquid dale automatic anti-stop function

The liquid dalle automatic anti-stop function automatically adjusts the vacuum pressure according to the amount of liquid agent remaining, preventing fluid leakage and air from the tip of the Nozzle, greatly contributing to improving production and quality.

If such a problem arises, the following problems may occur.

- Liquidant drops from the tip of Nozzle, causing unevenness to finish

- Air entanglement leads to unstable discharge volume

- A stoppage of the application line or redoing work is generated, reducing production efficiency.

▼

If there is a liquid dale automatic anti-stop function ...

Maintain stable quality

3.Automatic residual volume warning function

When the material is cut off, it not only interrupts the work, but also leads to a deterioration in the quality of the product and delay in the entire production line, leading to significant cost and time loss. In particular, if you continue to work without noticing that the material runs out, it may cause irreversible defects or delay delivery time to customers.

▼

However, there is a limit to manually checking the remaining amount, and it is difficult to accurately predict when the material runs out.

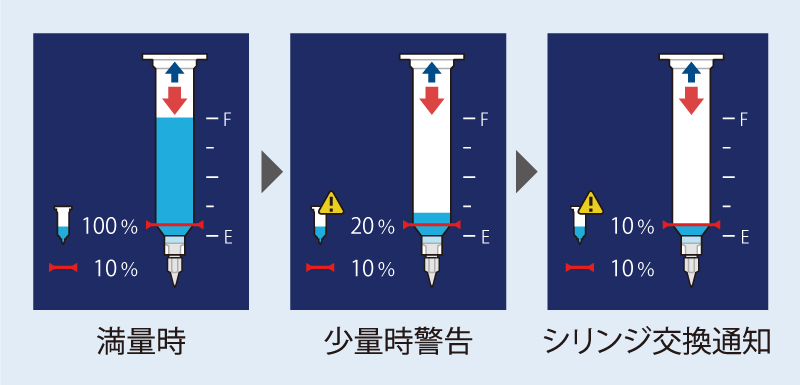

It is the automatic residual volume warning function that solves these issues.

Sensing and monitoring the remaining amount of liquid material in the syringe with high accuracy.

Accurately detects the remaining amount immediately before the material disappears and warns in two stages to prevent problems caused by interruption of work or running out of materials.

Full-function digital control Dispenser SuperΣCMIV

The products of the SuperΣ series with Σ3 major functions are as follows.

Please consider it as a partner that solves issues at the production site.