Thermal management solutions that support new technologies such as next-generation power semiconductors, 5G, and IoT

Case study 1 solution / 2 solution Heat dissipation material application

Challenges

- 2 Liquid Heat dissipation Gap Filler application uses MOHNO Type Dispenser,

Due to wear, it is necessary to replace the rotor and the stator once every two months, and the running cost is high (issue 1). - In addition, the application accuracy is poor with a small amount of application less than 1 g/shot, and it is difficult to apply quantitatively (Problem 2).

- We plan to use Heat dissipation material with a high viscosity 1 solution of 800,0000mPa・s or higher, but we do not know what Dispenser is best (Problem 3).

Measures

- Changed from MOHNO Type Dispenser to Dispenser, a planja pump system dedicated to Gap Filler.

- The screw Dispenser is introduced for Heat dissipation material with high viscosity 1 solution.

Effect

- Due to the change to a plunger pump system with less consumable parts, the overhaul cycle was reduced to one-third from two months to six months.

- Quantitative application was achieved at 0.5g/shot using the plunger pump method.

- We proposed a screw-type Dispenser for 1 solution Heat dissipation material with high viscosity and achieved the application requirements.

PROPOSED PRODUCTS

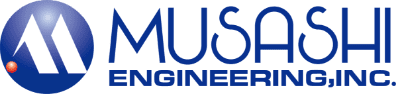

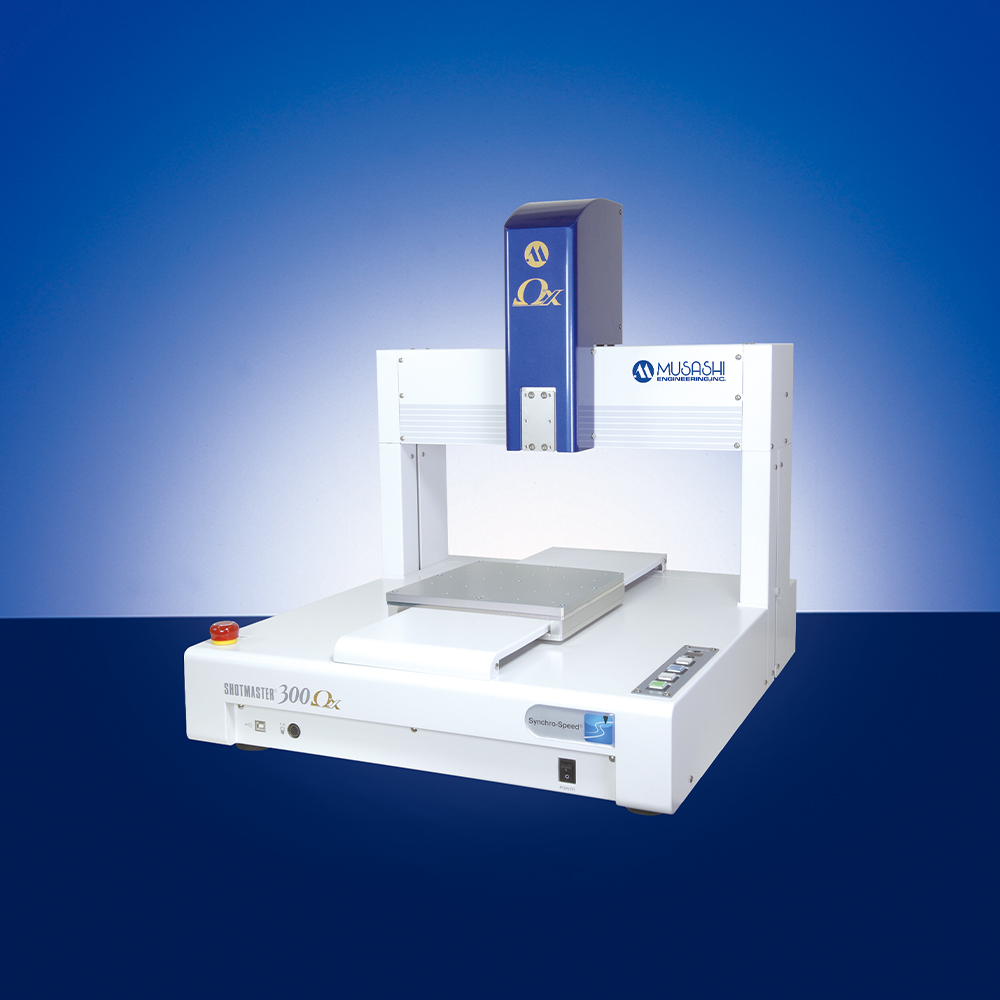

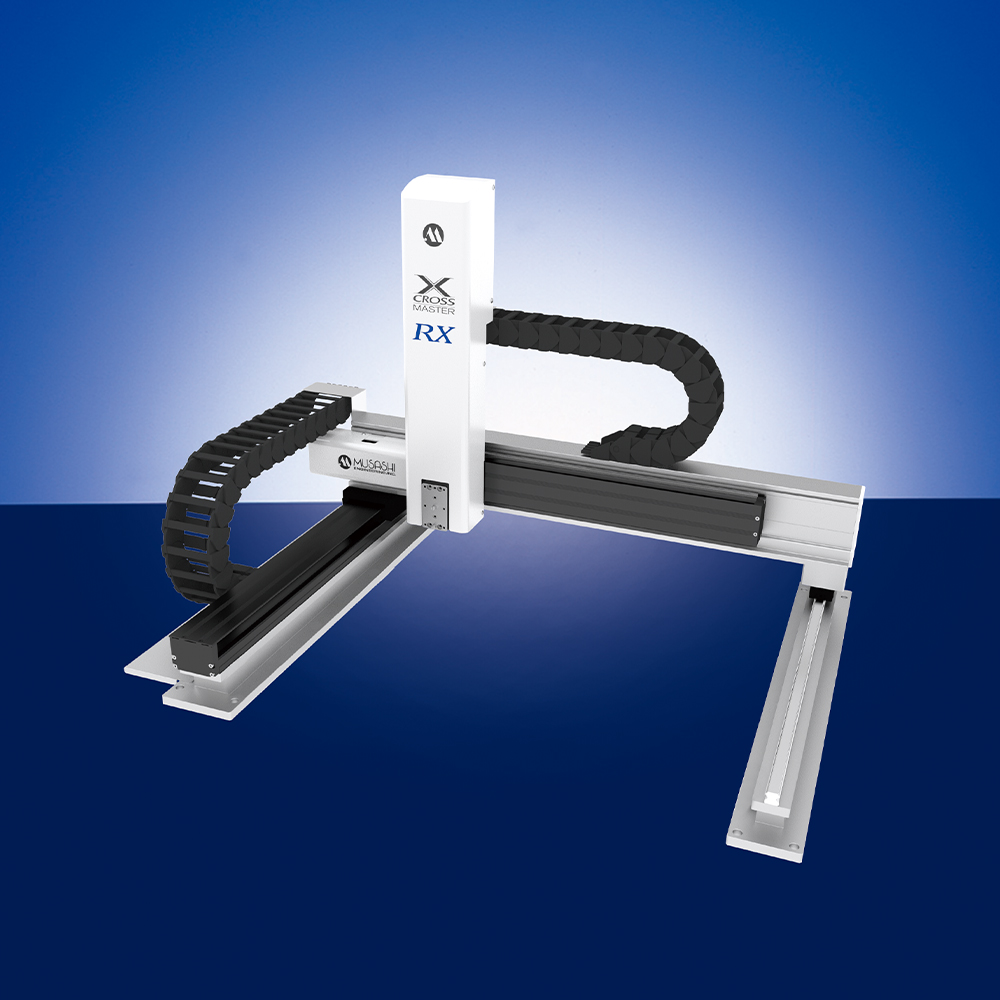

Proposed Products

OTHER CASES

Other Case Study

Filling chemical solution for screw cap tubes, conical tubes and vial bottles, and semi-automated cap opening and closing operations.

The adoption of liquid metals is progressing in CPU Heat dissipation, a high-performance gaming PC. High-speed and stable application with contactless Jet dispense.

Fast speed, no contact accident with workpieces, can be applied from lower, horizontal, and diagonally.

A conformal coating to protect mounting substrates (PCBs).

There is no problem even if the workpiece has different distortions or warpages, or if the workpiece is misplaced in the palette.

Catalog and Software Downloads

To download, you need to log in to this site.

If you have not registered for login, you can download it after registering here.

Contact