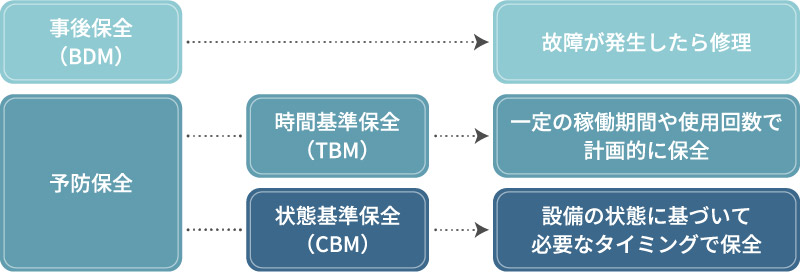

Evolution of equipment maintenance: post-maintenance (BDM), time-based maintenance (TBM), and condition-based maintenance (CBM)

Standard Maintenance (CBM)

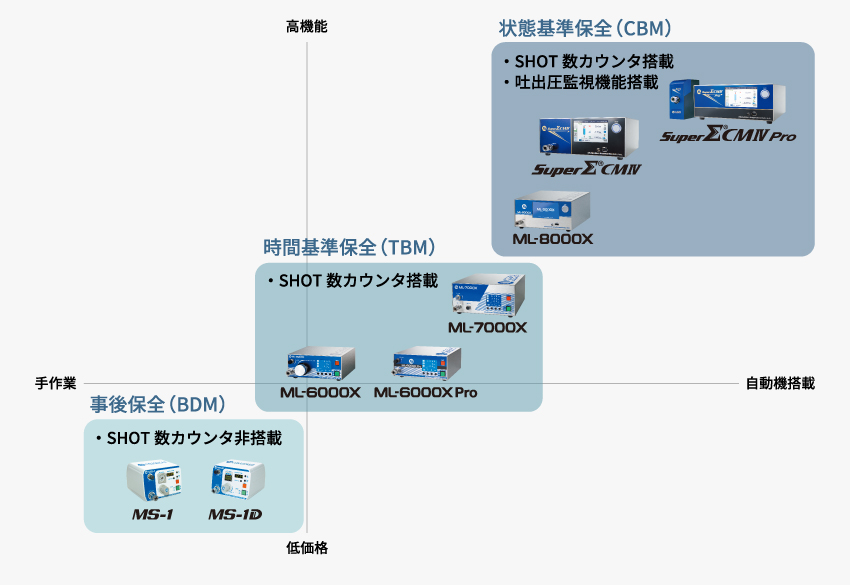

Not only in Dispenser, but also in manufacturing equipment, important equipment maintenance methods have evolved from post-maintenance (BDM) to preventive maintenance (TBM, CBM), and are moving toward future predictive maintenance (PdM). In this article, we will compare the characteristics and benefits of each product and introduce our related products.Post-maintenance (BDM) is the most basic conservation method.

Breakdown Maintenance is a method of repairing and replacing equipment after equipment fails. While initial investment is low, there is a risk of sudden downtime and repair costs. In case of sudden failure, there are many users who have spare equipment.

Time Standard Maintenance (TBM) is the first step in preventive maintenance.

Time-based maintenance is a method of performing regular maintenance based on a certain operating period and number of times of use. Planned maintenance is possible, but in fact, parts may be replaced without problems. In the past, the total number of SHOTs in Dispenser has been counted as a controller and used as a guide for replacing consumables.

State-based maintenance (CBM) is the evolution of data-based maintenance.

On the other hand, condition-based maintenance is a method of monitoring real-time data of equipment and performing maintenance based on conditions. This enables optimal maintenance at the time required, reducing waste and risk.

Compared to post-maintenance and time-based maintenance, CBM has the effect of optimizing maintenance frequency and reducing unnecessary costs, as well as improving the reliability of equipment.

Difference between post-maintenance and preventive maintenance (TBM/CBM)

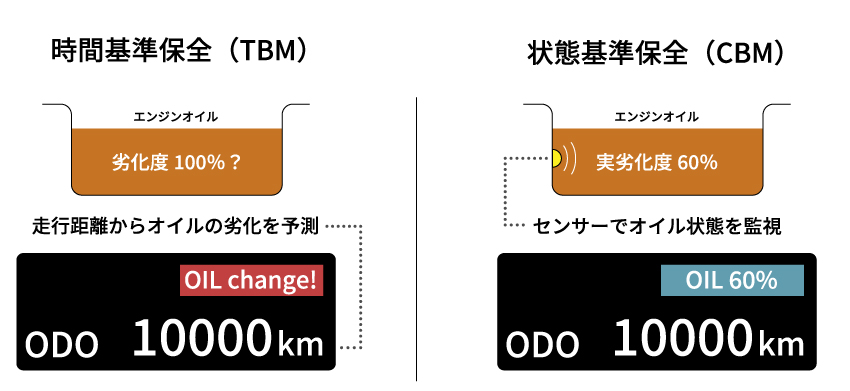

For example, in the case of a car, it is common to change engine oil regularly, judging from the mileage and duration of the car. The guide varies depending on the driving conditions of the car, so it is difficult for the driver to accurately calculate when replacement is required. In recent years, not only simple mileage, but also vehicles that encourage oil change by comprehensively judging the speed of engine rotation and the frequency of short-distance driving, and vehicles that directly measure the quality of oil have been born. The information provided by these vehicles is more accurate to determine oil degradation and enable maintenance at the right time.

Time Standard Maintenance (TBM) and State Standard Maintenance (CBM) in engine oil change

CBM realized by our products—the strength of real-time monitoring function

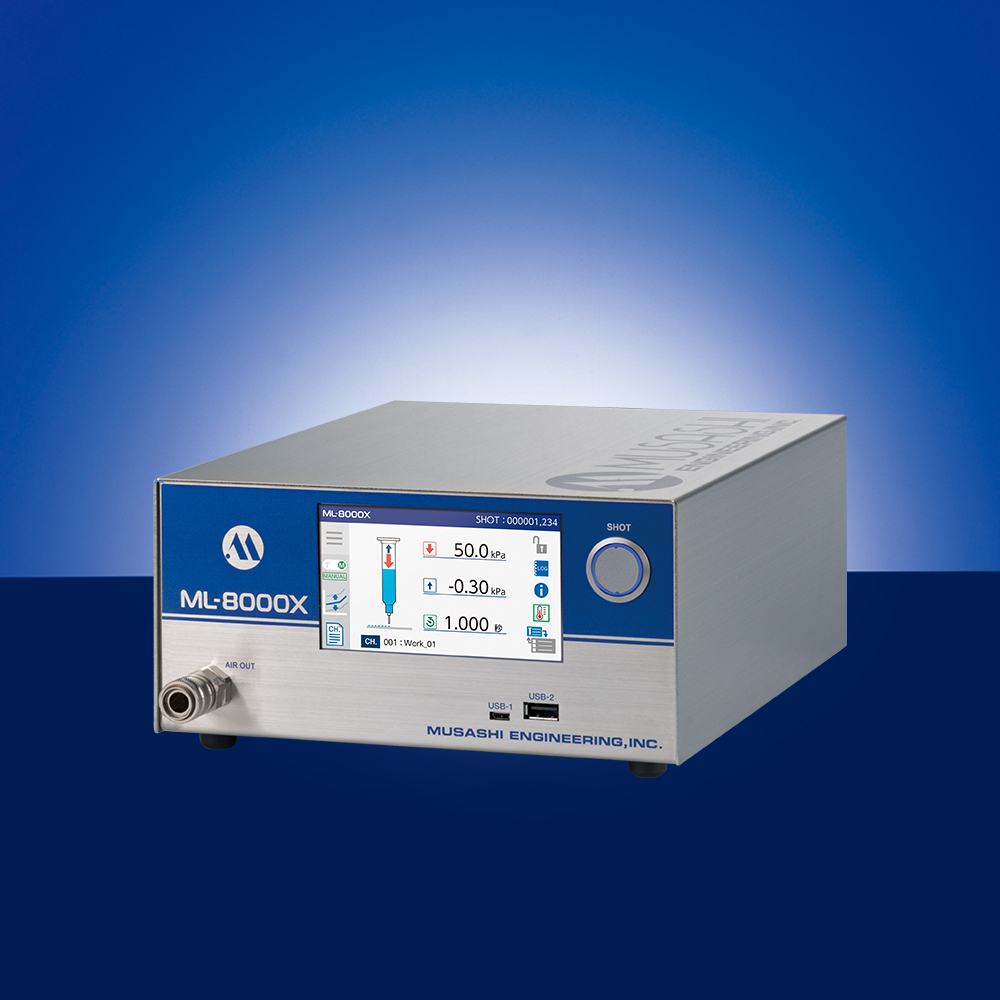

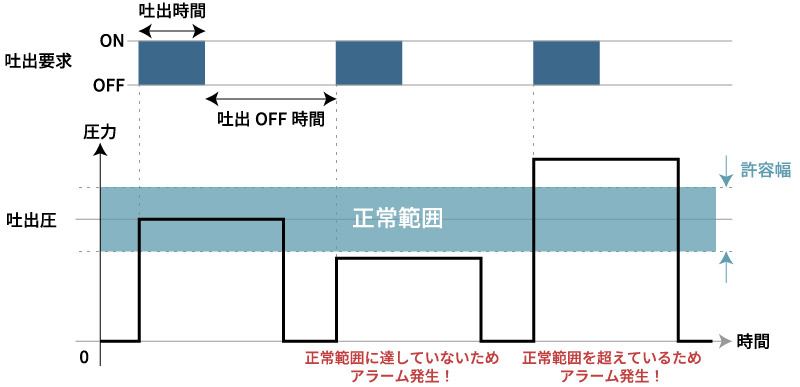

Among our air pulse Dispenser, the ML-8000X and SuperΣCMIV series are equipped with the "Exit Pressure Monitoring" function as new features. This allows you to monitor whether the pressure coming out of the Dispenser is as set for each discharge operation. We can optimize maintenance timing and reduce unnecessary costs by combining the frequency of the alarm with the occurrence of defects at the customer's production site, as well as using the alarm to know when an abnormal discharge occurred.

Output pressure monitoring function

Our air pulse Dispenser lineup and types of maintenance

View the product information of Dispenser equipped with "vomit pressure monitoring" function

Please refer to the following explanation for the type of Dispenser.

Predictive Maintenance (PdM): Future Facility Management Trends

Predictive Maintenance is a method that uses AI and machine learning to predict the risk and timing of equipment failure and achieve even more efficient maintenance. It is an extension of CBM and is attracting attention as a next-generation conservation technology. Monitoring and storing data in real time with CBM is the first step toward predictive maintenance.

Summary — Efficient maintenance management starting with CBM

Equipment maintenance has evolved from post-maintenance to preventive maintenance (TBM, CBM) and predictive maintenance. Our products provide monitoring functions as an important basis for achieving condition standard maintenance (CBM) and support the efficiency of equipment maintenance. Please consider our solutions to realize the next generation of equipment management.

Please consider our solutions to realize the next generation of equipment management.

Recommended catalog

ML-8000X

SuperΣCMⅣ

SuperΣCMⅣ Pro