How to choose the best needle Nozzle for liquid application| Musashi Engineering, Inc.

Information on the type and selection of needle Nozzle made by Musashi Engineering.

Please use it for product selection.

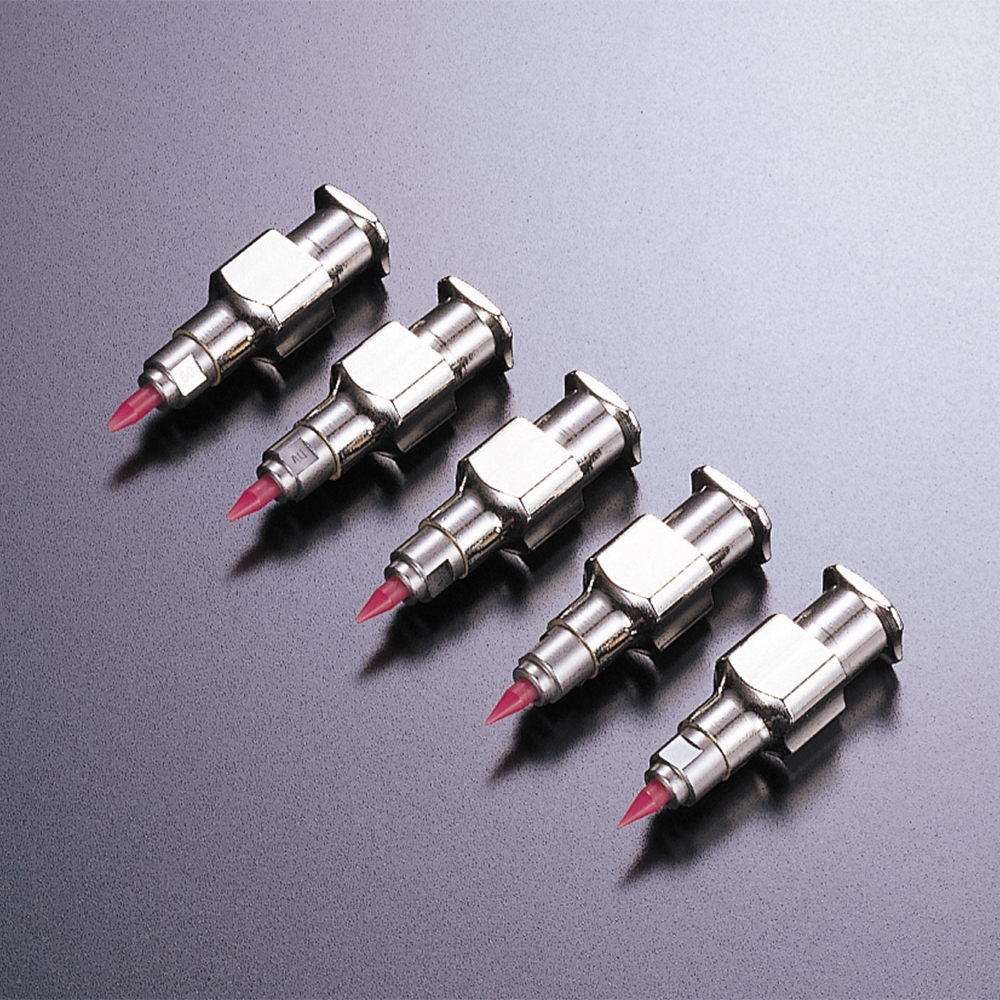

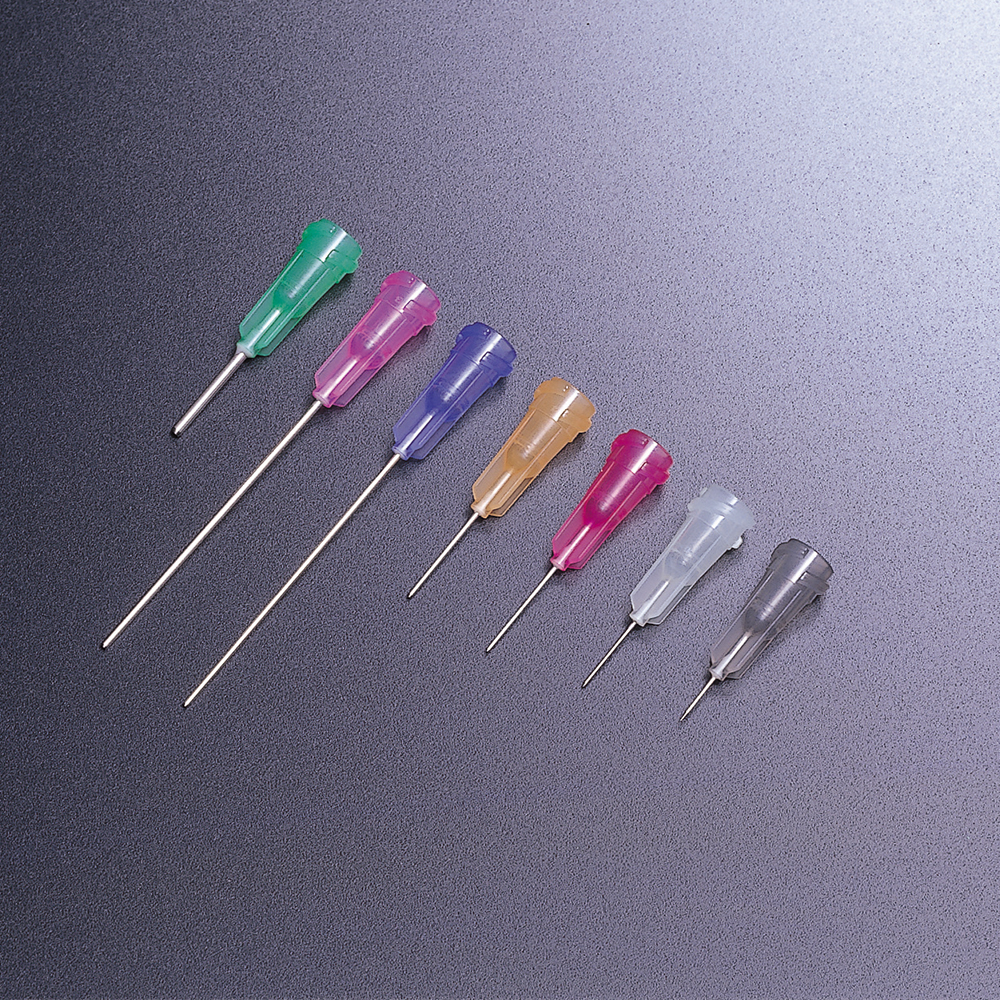

| Plastic Needle |

Article 2 screw plastic needle | Metal needle | Thin metal needle | |

|---|---|---|---|---|

| Model | PN- □□ G-A PN- □□ G-B |

DPN- □□ G-◇ (◇=0,1,2,3) |

SNA- □□ G-B SNA- □□ G-C |

SNA-0. □□ N-4L-F SNA-0. □□ N-6L-F |

| Appearance |  |

|

|

|

| Material | Needle base: Polyacetal Needle: Stainless steel |

Needle base: Polypropylene Needle: Stainless steel |

Needle base: Brass (Ni plating) Needle: Stainless steel |

Needle base: Brass (Ni plating) Needle: Stainless steel |

| Needle length | 8mm(-A) 13mm(-B) |

6.4mm 12.7mm 25.4mm 31.8mm 4 types |

13mm(-B) 15mm(-C) |

4mm 6mm |

| Length specification | Not possible | Not possible | Allowed | Allowed |

| UV support | △ | × | 1 | 1 |

| Anaerobic response | × | × | × | × |

| Application | Standard Nozzle | Article 2 The feeling of mounting screws Abundance of needle length |

Pharmaceutical resistance Length can be specified |

Hard to interfere with walls and parts |

| Article 2 screws Tapa Nozzle |

PTFE Nozzle | PTFE Nozzle with SUS Guide | Soft needle | |

|---|---|---|---|---|

| Model | TPND- □□ G-U | TN- □□ G TN- □□ G-U |

TN- □□ G-○○L- □□ G-△△L | PPN- □□ G |

| Appearance |  |

|

|

|

| Material | Needle base: Polyethylene Needle: Polyethylene |

Needle base: Polyacetal Needle: Fluoropolymer |

Needle base: Polyacetal Needle: Fluoropolymer ※With SUS Guide |

Needle base: Polypropylene Needle: Polypropylene |

| Needle length | 38.1mm (Length) | 8mm | Order production with specified dimensions | 35.9mm |

| Length specification | Not possible | Allowed | Allowed | Not possible |

| UV support | 1 | 1 (-U only) | △(Respond to custom orders) | × |

| Anaerobic response | 1 | 1 | 1 | 1 |

| Application | High viscosity material orientation | For anaerobic materials Prevention of workpiece damage |

Easy to position at the tip of the Nozzle | Can be applied according to the workpiece |

| Article 2 screws Precision Solid Nozzle |

High-definition Nozzle | Sharp needle | Curve needle | |

|---|---|---|---|---|

| Model | DSHN-M2 | FN-0. □□ N FN-0. □□ ND |

SPN | CPN- □□ G-A45 CPN- □□ G-B45 CPN- □□ G-A90 |

| Appearance |  |

|

|

|

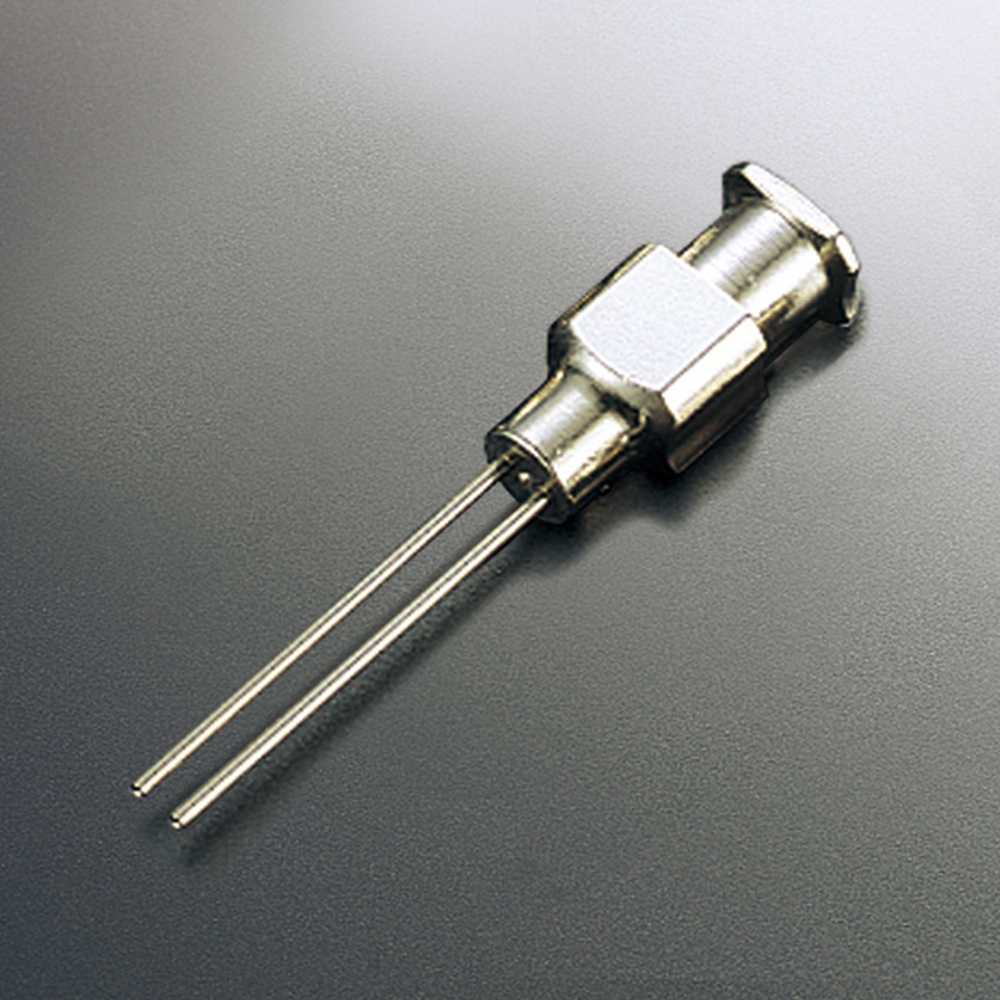

| Material | Needle base: Stainless steel Needle: Stainless steel |

Needle base: N-shaped brass (Ni plating) ND type stainless steel Needle: Non-disclosure |

Needle base: Polypropylene Needle: Stainless steel |

Needle base: Polypropylene Needle: Stainless steel |

| Needle length | 18.25mm (Length) | Type N: 23.0mm Type ND: 22.2mm (Length) |

Depending on the nozzle diameter | 12.7mm(-A) 38.1mm(-B) |

| Length specification | Not possible | Not possible | Not possible | Not possible (SNA bendable) |

| UV support | 1 | × | × | × |

| Anaerobic response | × | × | × | × |

| Application | Hard to clogging material with filler Reduced discharge time |

For micro and micro applications | Reducing the crawling of low viscosity materials | Difficult to access Can be applied to places |

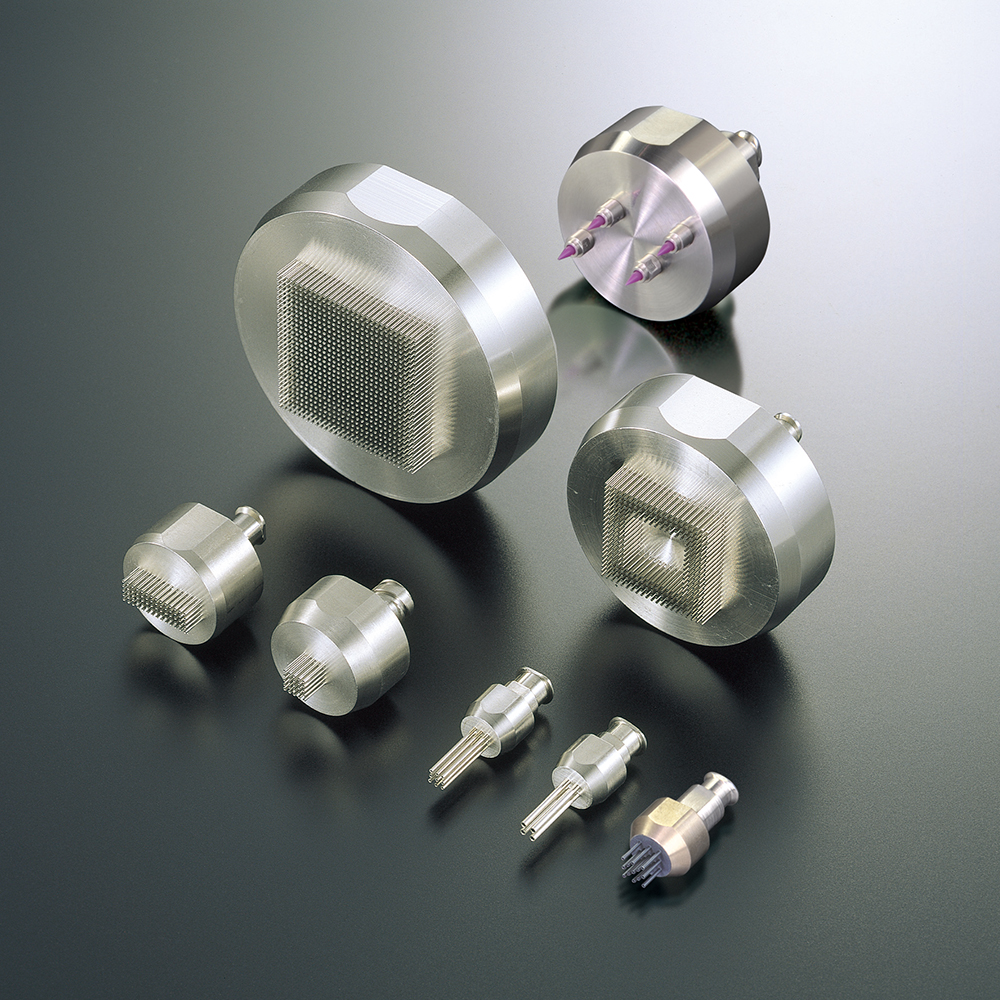

| Slit Nozzle | Multi-Nozzle | Hake Nozzle | Multi-point discharge needle | |

|---|---|---|---|---|

| Model | - | MN | BN-S◇ (◇=1,2,3,4) |

DN |

| Appearance |  |

|

|

|

| Material | Needle base: Stainless steel Needle: Stainless steel |

Needle base: Stainless steel Needle: Stainless steel |

Hake Department: Polyester fiber |

Needle base: Brass (Ni plating) Needle: Stainless steel |

| Needle length | ー | Order production with specified dimensions | S1,S2:(6.4mm) S3,S4:(10mm) |

20mm |

| Length specification | Specify the width and thickness of the slit | Order production with specified dimensions | Not possible | Allowed |

| UV support | 1 | 1 | × | 1 |

| Anaerobic response | × | × | × | × |

| Application | Surface application For beta-painting |

For multi-point discharge and surface-shaped application | For brush-painting and brush-painting applications | Multi-point discharge is possible |

Recommended catalog

Part Accessories & Valves/Tank Catalog

What is Needle Nozzle?

Needle Nozzle is one of the key parts to achieve high-quality application at the manufacturing site. In order to respond to a wide range of applications, such as discharge, adhesion, and painting of precise liquids, there are various types and shapes, and the right selection according to the characteristics and applications of the product greatly improves the efficiency and quality of the manufacturing process.

In this article, we will explain in detail the broad lineup of Musashi Engineering's Needle Nozzle and the points of selection.

※Our company does not refer to the Nozzle Needle but the Needle Nozzle.

How to choose Needle Nozzle

There are four key points when selecting Needle Nozzle.

- Select Nozzle of material that matches the type of liquid agent

- Select Nozzle with a shape that matches the viscosity of the liquid

- Select the Nozzle that matches the shape of the object to be applied (work)

- Select the Nozzle that was in the shape of the application

- 1 Select Nozzle of material according to the type of liquid agent

The material of the needle Nozzle is broadly classified into metal or resin. For example, if the liquid is a material that is not compatible with resins such as organic solvents, it is desirable to select a metal. On the other hand, when dealing with materials that are reactive to metal, such as anaerobic adhesives, it is necessary to select a resin.

| Made of metal | Made of resin |

|---|---|

|

|

In addition, not only reactivity with liquid agents but also the presence or absence of permeability may be a condition for judgment. When using UV-curable resin that reacts and hardens with UV light, it is necessary to use a needle Nozzle made of materials that do not pass UV light.

| Transmitting UV | It does not pass through UV |

|---|---|

|

|

- 2 Select Nozzle in shape according to the viscosity of the liquid agent

The shape of the needle Nozzle is broadly classified into straight and taper shape. Nozzle, which has a straight shape, generally has a pipe shape with a certain length, so the piping resistance is high and the high viscosity liquid is difficult to flow, but it has the advantage that low viscosity liquid is difficult to liquidate. On the other hand, Nozzle, which has a taper shape, has a small resistance during liquid discharge and has excellent fluidity, making it suitable for expelling high viscosity materials in a short time.

| Straight shape | Taper shape |

|---|---|

|

|

| Low viscosity material is hard to liquidate | Easy to discharge high viscosity material |

- 3 Select the Nozzle that matches the shape of the object to be applied (work)

Depending on the shape of the workpiece, the point of selection is whether you can access the place Nozzle wants to apply. For example, if a taper shape is used, a straight-shaped Nozzle is used, or a product with a long needle tip is used. Depending on the workability, Nozzle made of resin that is difficult to damage the workpiece may be suitable. There is also a lineup of curved Nozzle that can penetrate narrow areas.

- 4 Select the Nozzle that was in the shape of the application

In many adhesive processes, application shapes of dots and lines are used, but special Nozzle can be applied in different shapes. A typical example is Slit Nozzle, which allows you to perform coating in a single application operation.

| Dot dispensing-line application | Surface application | Ta Dot dispensing |

|---|---|---|

|

|

|

|

|

|

Recommended for those who want to try various Nozzle!

Nozzle Kit

Reduce these four points and select the best Nozzle according to your purpose. When choosing the type and size of Nozzle, we also recommend the Nozzle kit with a basic Nozzle set. There are nine types of Nozzle in total. Of course, if you have any questions or concerns about the selection or application evaluation, please contact us.