Peripheral device, accessories

accessory Peripheral device, accessories

We have a lineup of products that improve workability and quality of application related to application.

Musashi Engineering also handles liquid tanks (pressure vessels). The essential components of the liquid tank and the points for selecting tank configuration are also summarized on the "What is pressure vessel?" page below, so please take a look.

What is a pressure vessel?

accessory LIST Peripheral device, accessories List

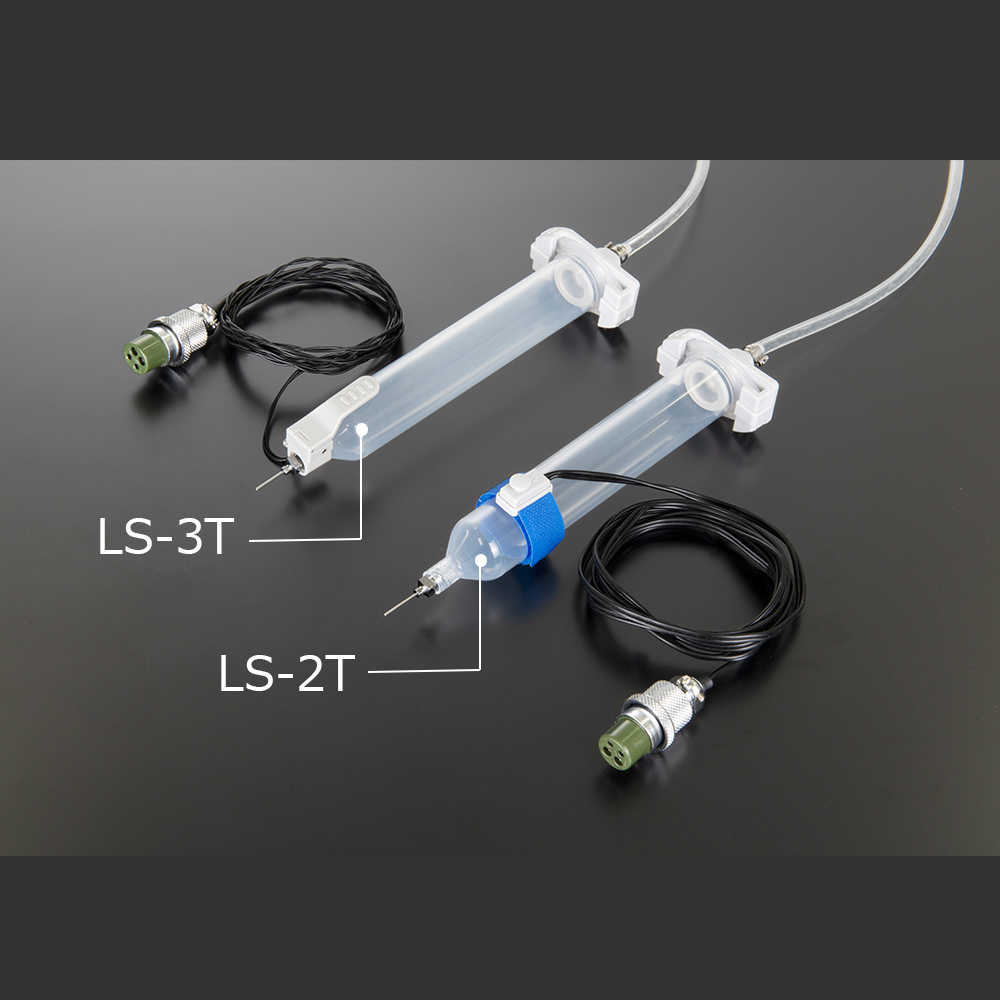

Adaptor tube

The stopper ensures that the syringe is fitted with one-touch. Its high airtightness makes it effective for stable application.

Temperature unit

We propose temperature control systems and temperature control systems that match liquid properties and operating environment conditions, such as overheating cooling systems and high-temperature heating systems.

Stirring unit

Functional liquid materials are often composite materials, including fillers, etc. The mixing unit is an expansion option product aimed at preventing the deposition of fillers in liquids.

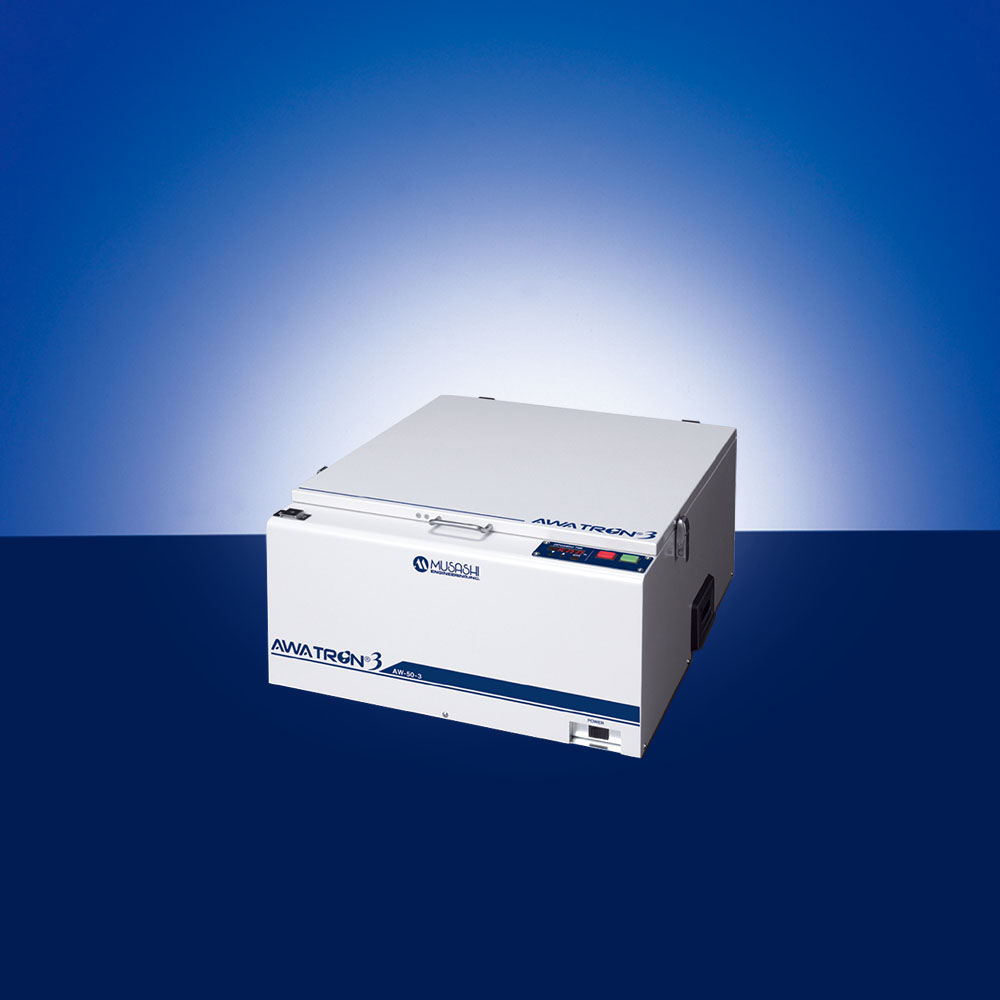

Defoaming machine

It is easy to use, reliably, and speedy defoaming. Just set the syringe, close the lid, and press the start button to defoam. By removing the bubbles in the syringe, further stable application is realized.

Cartridge

We have a large number of medium-sized general-purpose containers according to daily usage and replacement frequency. It can be used for a variety of applications, from manual work to automatic mounting.

Tank / High Pressure Pump

Four types of tanks, direct input type and inner container type, and various capacities are available according to the application and liquid characteristics, so we can propose an optimal tank valve system configuration.

Other accessory

Other offers many products that contribute to high-precision application.

Catalog software

Download

To download, you need to register as a member on this site.

If you have already registered as a member,

After logging in from here,

You can download it.

If you have not registered as a member,

After registering as a member from here,

You can download it.

Click here for inquiries

By phone

Click here for inquiries

From the form

Click here for inquiries