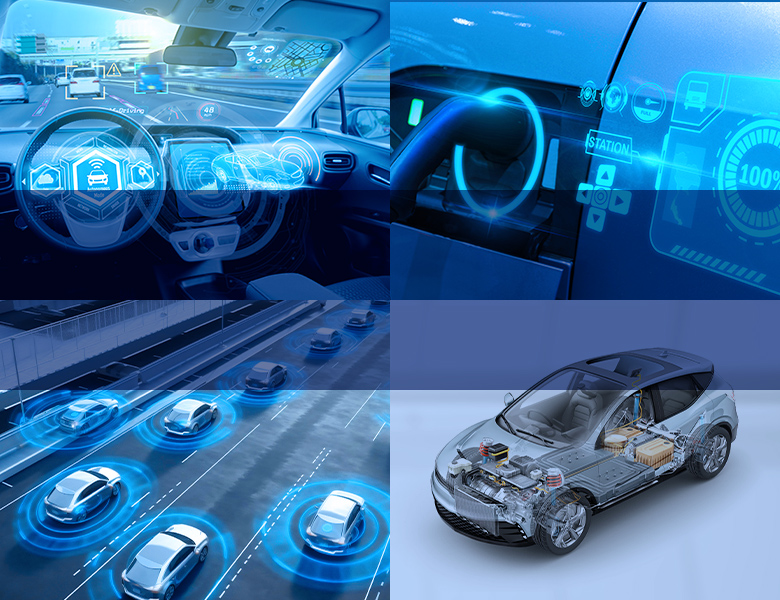

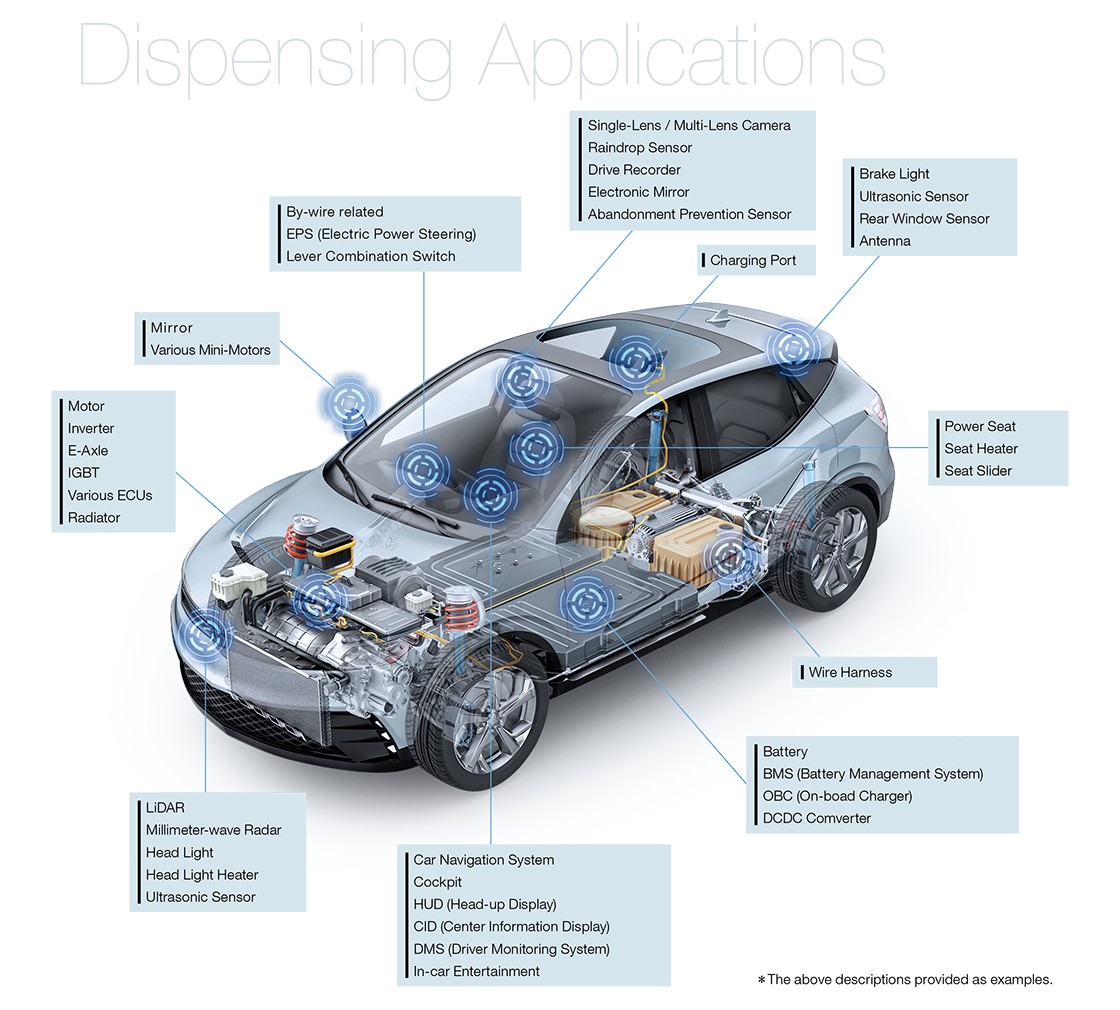

In recent years, the electronicsization of automobiles has progressed rapidly, and the number of electronic components installed in them has been increasing steadily.

As the main motor to replace the engine, the diversified HUD/CID, and the ADAS evolves.

Generalized camera sensors, radars, etc.

MUSASHI is a dispense technology that supports innovative manufacturing.

We will continue to challenge the new era of car electronics to contribute to the production of automotive parts that are directly connected to safety.

High precision

No.1 Dispenser manufacturer

High precision application technology.

Quality improvement

High speed

Non-contact application “JET dispense”

Fastening technology to start.

Tact UP

Reduce consumption and improve maintainability

Reduction of material loss, reduction of consumable parts,

Realize reduction of programming man-hours.

Cost reduction

Solution-01 Car Electronics

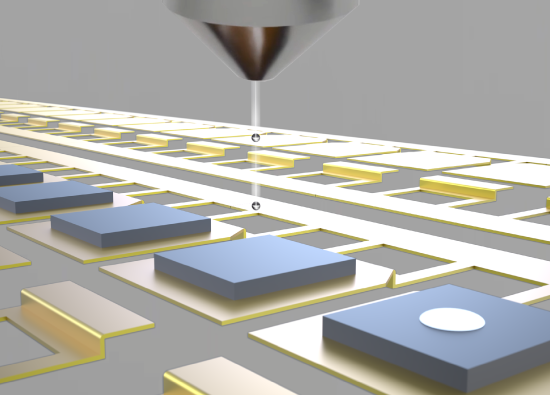

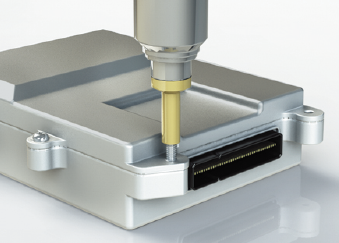

Solder paste

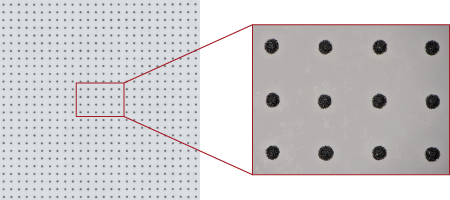

Solder paste type-8 support※

Φ100μm 1 million SHOT can be applied stably

※The corresponding material depends on the manufacturer's specifications.

Type 8φ100μm After 1 million shots

Diode clip mount

- Recommended

Dispenser -

1

Solder Paste Jet Dispenser

- New structure that does not contain particles

Our company's completely new structure was created by thoroughly investigating the cause of clogging solder. Ag paste and Au paste can also be applied stably. - Not affected by step

It is difficult to apply in the printing process, suitable for steps and cavity. - High-speed production is possible

High production capacity is achieved without the need for Nozzle up and down operation during application.

- Recommended Full Automatic

Machine -

2

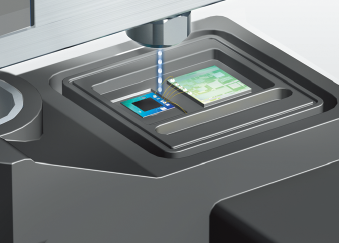

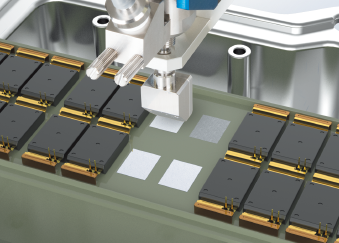

Fully automatic high productivity dispense machine

- Stop production, dispense machine

Head maintenance is possible during production. It can be processed simultaneously with multiple heads. You can minimize idle time. - Reduce downtime by attaching and removing head one touch

- People and things related to the equipment

Equipped with reliable traceability system - Installation of camera for internal monitoring

Contributed to shortening the time to investigate the cause of trouble.

Case Study of Other

Adhesive/protective agent

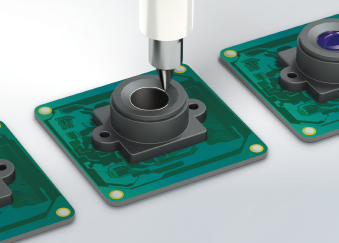

3 Silicone sealing of sensor parts

Adhesive/protective agent

4 UV application with fixed in-vehicle camera lens

Substrate coating

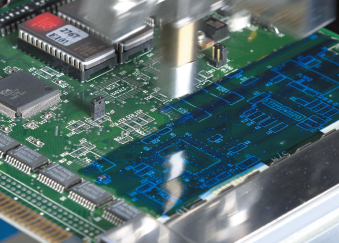

5 Coating to BMS substrate

Potting

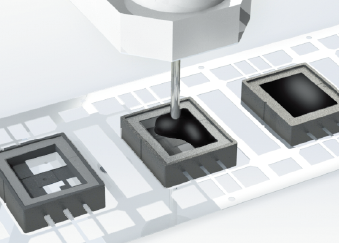

6 Sensor Parts Potting

Potting

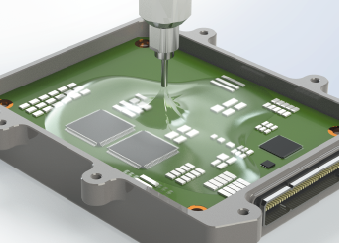

6 Putting to ECU

Solution-02 Automotive electrical components/OBC/Inverter

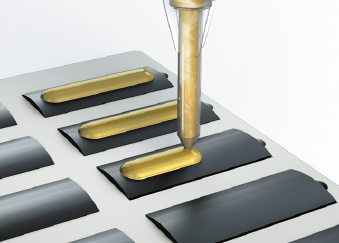

Liquid Heat dissipation Material

Heat dissipation grease application

6 Heat dissipation grease application to ECU housing

Liquid Heat dissipation Material

Heat dissipation Gap Filler

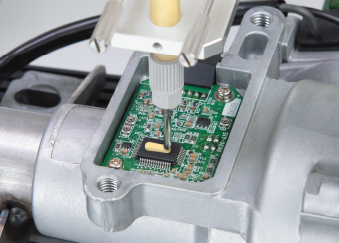

7 Electric Power Steering (EPS)

Heat dissipation Gap Filler Application

Liquid Heat dissipation Material

Sintering paste

6 To SiC MOSFET modules

Heat sink attachment

Gasket

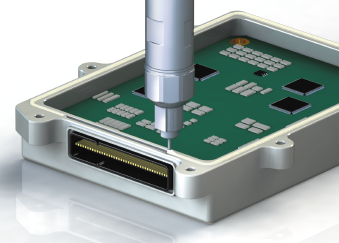

8 CIPG application to ECU

Gasket

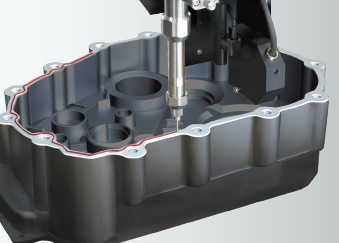

8 FIPG application to engine parts

Screw tightening

Screw tightening of ECU case

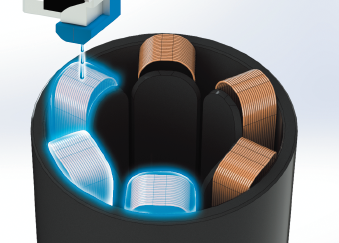

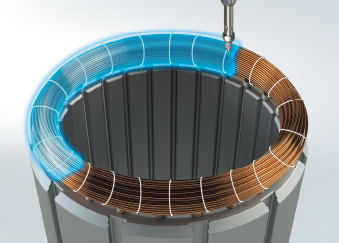

Solution-03 Automotive Motor (e-Axle)

Varnish impregnation

9 Apply varnish to DC motor coil

Varnish impregnation

8 Apply protective agent to the motor coil

2 Liquid adhesive

6 to motor magnet

2 Liquid adhesive application

Solution-04 Other Automotive Parts

Grease

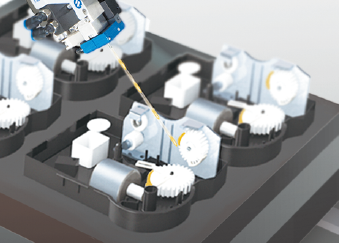

9 Grease application to the gear part

Grease

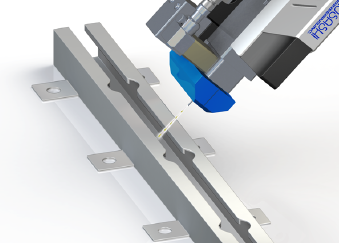

9 Grease application to seat rail

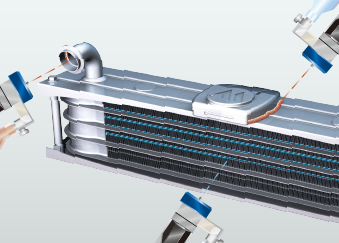

Flux and wax material

9 Application of wax material to heat exchanger

Recommended catalog

Automotive

Dispense

Solution

Heat control (Heat dissipation material)

Solution

2 Liquid Dispense Solution

SOLDER JET

FAD2500W

DUAL MPP-5-M-GF-MINI

OTHER CASES

Other Case Study

A thermal management solution that supports new technologies such as next-generation power semiconductors, 5G, and IoT.

Fast speed, no contact accident with workpieces, can be applied from lower, horizontal, and diagonally.

A conformal coating to protect mounting substrates (PCBs).

There is no problem even if the workpiece has different distortions or warpages, or if the workpiece is misplaced in the palette.

Technology Columns

Recommended Technical Column

Contact